In a vehicle’s steering system, the steering link is a critical component responsible for accurately transferring the driver’s steering wheel input to the wheels, ensuring the vehicle moves in the intended direction.

In everyday conversation, people often use steering link and steering linkage interchangeably, but they are not exactly the same.

- Steering linkage refers to the entire system of interconnected rods, joints, arms, and other components that work together to steer the wheels.

- Steering link, on the other hand, refers to an individual rod within that system—typically the one that connects the steering gear to the steering arm, or the steering arm to the wheel assembly.

A steering link is a part, while the steering linkage is the system.

Although many technical manuals and parts catalogs blur the line between the two, distinguishing them helps in having more precise discussions about design and applications.

Why Steering Links Are Essential?

Whether it’s a passenger car, a heavy-duty truck, agricultural machinery, or construction equipment, the steering link is one of the core components that enables accurate and responsive steering. Its main roles include:

- Transmitting steering force – Converting the rotational motion from the steering wheel into linear motion that pushes or pulls the wheels.

- Keeping wheels in sync – Ensuring both left and right wheels turn at coordinated angles, preventing pulling or steering irregularities.

- Maintaining stability and safety – Providing consistent steering response under high speeds, heavy loads, or challenging terrain, reducing the risk of losing control.

If a steering link is missing, severely worn, bent, or loose, it can lead to:

- Delayed steering response or poor feedback from the steering wheel

- Increased and uneven tire wear

- Reduced vehicle stability at higher speeds

- In extreme cases, complete loss of steering control

In short, the steering link acts as the “bone” of the steering system, supporting both accuracy and reliability in movement. Whether a vehicle is cruising on a highway, working in the fields, or maneuvering at a busy port, it needs a steering link that is strong, stable, and durable to ensure safety and operational efficiency.

2 Basic Functional Demonstrations

10 Applications Using Steering Links

1. Passenger Cars / Light Trucks / Racing

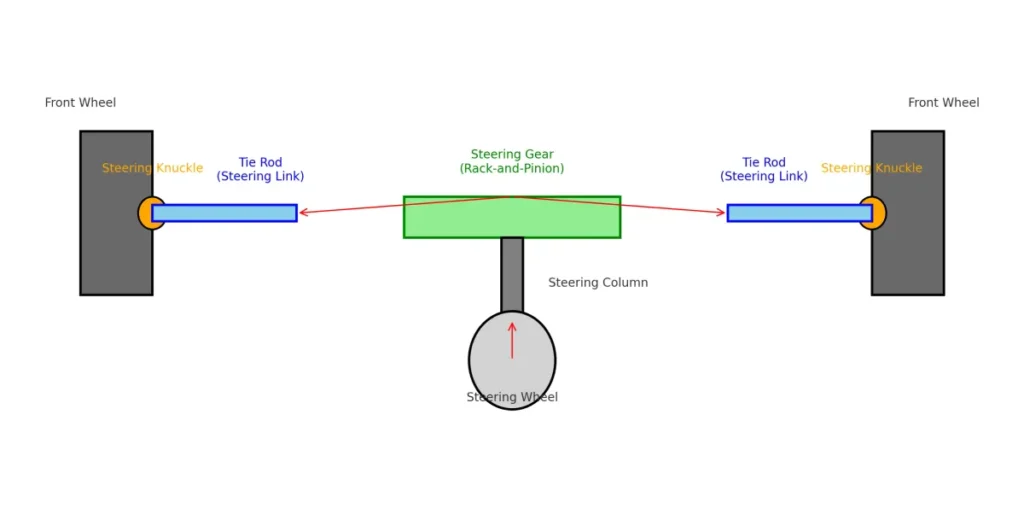

In passenger cars and light trucks, the steering link typically works with a rack-and-pinion steering system, connecting the steering gear to the front wheels to deliver precise and direct steering response.

For everyday driving, this setup provides light steering feel and high accuracy.

In motorsports, however, the performance requirements for steering links are much higher—they must remain rigid under high speeds and heavy loads, while delivering extremely quick response to handle sharp turns and rapid lane changes. Racing engineers often fine-tune the link length, mounting points, and even use lightweight materials to optimize handling for specific track conditions.

2. Heavy-Duty Trucks / Buses / Commercial Vehicles

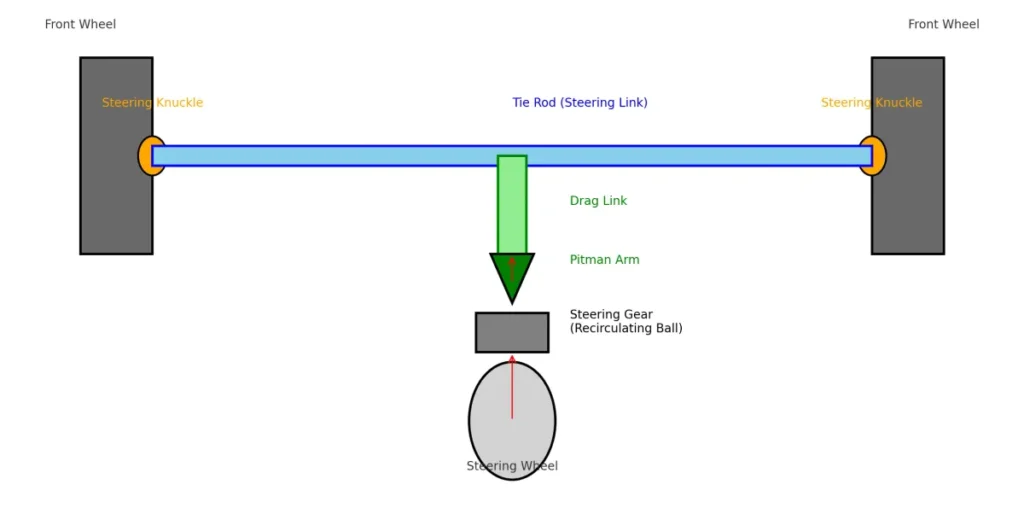

In heavy-duty trucks and buses, steering links face the challenge of high loads and prolonged operation.

These vehicles often use a recirculating ball steering mechanism in combination with a drag link to transmit steering force.

Because of the high rigidity of the front axle and the large tire diameter, the steering link must withstand significant torque and impact, which is why forged alloy steel is commonly used, along with reinforced ball joints for extended service life.

In addition, long-haul commercial vehicles may incorporate a steering damper into the steering link system to reduce steering wheel vibration and driver fatigue during extended trips.

3. Agricultural Machinery

On tractors, harvesters, sprayers, and other agricultural equipment, steering links must operate in mud, dust, and wet field conditions.

To ensure precise steering in such harsh environments, agricultural steering links often feature sealed designs to keep out debris, along with corrosion-resistant coatings such as zinc plating or powder coating.

Some large-scale farming machines also integrate steering links with hydraulic steering systems, enabling large steering angles at low speeds for easy turning and precise maneuvering in the field.

This adaptability not only improves operational efficiency but also reduces downtime caused by steering component failures.

4. Construction Equipment

In construction equipment such as loaders, graders, and bulldozers, steering links must maintain reliable performance under heavy loads and strong impacts.

These machines often operate on uneven, rugged terrain and require large steering adjustments, making strength, toughness, and wear resistance top priorities.

Construction steering links are typically made from thick-walled tubing or heat-treated steel, fitted with heavy-duty ball joints to improve impact resistance. Protective sleeves or rubber boots are often added at key connection points to prevent debris and dirt from entering the joints.

In some large machines, steering links are integrated with hydraulic cylinders to provide greater steering force and flexibility.

5. Specialty Vehicles

Specialty vehicles—such as military armored vehicles, port container tractors, and airport shuttle buses—place even higher demands on steering links.

Military vehicles must deliver reliable steering performance in extreme temperatures, sandstorms, or humid jungle conditions, often using high-strength alloys and military-grade anti-corrosion coatings.

Port and airport service vehicles focus on low-speed, large-angle maneuverability, as well as durability during long hours of continuous operation.

These steering link designs often combine high-precision machining with modular construction, allowing for quick component replacement between missions to minimize downtime.

6. Marine Applications

In mechanical steering systems for small boats, yachts, and certain outboard motors, the steering link transmits motion from the tiller or steering wheel to the rudder or outboard motor steering assembly.

Marine environments are highly corrosive to metal components, so marine steering links are typically made from stainless steel, nickel-plated alloys, or anodized aluminum.

Waterproof sealing is also essential to prevent seawater, salt spray, and moisture from entering the joints, extending service life and ensuring smooth steering performance.

7. Aerospace Applications

In the aerospace sector, steering links are primarily used in ground support vehicles, airport tow tractors, and certain aircraft directional control systems.

For example, in an aircraft’s nose landing gear steering system, the steering link transmits control inputs from the cockpit to the steering actuator, enabling precise ground maneuvering and docking.

Given the high safety and precision requirements in aviation, these steering links are often made from aerospace-grade alloys, manufactured to tight tolerances, and subjected to rigorous quality inspections to ensure consistent performance in varying climates and operating conditions.

8. Railway Maintenance Vehicles

Railway maintenance vehicles—such as track inspection cars and track maintenance machines—operate in environments very different from road vehicles but still require reliable and responsive steering systems.

When maneuvering in narrow rail sections or maintenance areas, steering links must provide precise control to prevent collisions with tracks or other equipment.

To meet the special conditions of railway operations, steering links are often equipped with vibration-damping structures, reinforced connectors, and dust- and mud-resistant designs at critical joints.

9. Mining Vehicles

In mining environments, whether in large haul trucks or underground transport vehicles, steering links must withstand intense impact, heavy loads, and harsh operating conditions.

Dust, debris, and moisture in mining sites pose significant threats to steering systems, so mining vehicle steering links are typically built with sealed constructions and high-strength wear-resistant alloys.

Some mining equipment also incorporates monitoring sensors into the steering link to track wear in real time, allowing for proactive maintenance to avoid unplanned downtime.

10. Amusement Ride Vehicles and Airport Ground Support Equipment

In amusement park vehicles—such as track-based ride cars and sightseeing shuttles—steering links ensure a safe and smooth steering experience.

These systems are designed for smooth operation, low noise, and high safety redundancy.

In airport ground support equipment, such as jet bridge tractors and baggage carts, steering links focus on precise low-speed maneuverability for tight spaces while maintaining durability for extended operating hours.

Steering Links Remain Critical Across Industries

From passenger cars to mining trucks, and from marine vessels to aerospace ground vehicles, steering links are a common yet indispensable component in countless mechanical steering systems.

Their role—transmitting force, synchronizing wheel movement, and ensuring precise control—remains the same, but their designs adapt to the specific challenges of each industry.

In every environment, the steering links application demonstrates one key truth: without them, safe and accurate directional control simply wouldn’t be possible.