SYZ RODENDS

Your Trusted Components Manufacturer

Titanium Parts

We are a highly experienced component manufacturer, offering titanium parts for high-end automobiles, motorcycles, and racing cars. With our extensive customization capabilities, we also produce other titanium parts according to your requirements.

High Precision CNC Machining Titanium Parts

Our Titanium Parts

Here are some of our titanium parts, custom cnc titanium products are not available for display due to DNA.

Please email to [email protected] with details if you request a custom service.

Request A Full Products Catalog

At SYZ Machine, we provide support at all times. Just 3 steps to start now!

1, Tell Us What You Need: Send us your request with details and share your idea.

2, Get Solution and Quote: We will work on the best solution base on your request and send you a specific quote within 24 hours.

3, Support at All Times: Whether it is before or after the sale, we are always here to support you.

Please submit the form or email to [email protected]

Why Choose SYZ RODENDS

Your Reliable Supplier

Extensive Experience

We have over 20 years experience in components manufacturing that allows us to stay ahead of the competition and deliver solutions to meet your needs.

Quality Assurance

We adhere to strict quality control standards to ensure that every product with the highest quality and demonstrating durability and performance.

Shipping

We will keep you up to date on the progress of your order, ensuring on-time delivery keeps your operations running smoothly without any disruption.

Customer Service

Our professional customer service team is dedicated to providing prompt and personalized assistance to ensure your satisfaction throughout the process.

Advantages of

Titanium Alloy

- Exceptional Strength: Exhibits impressive tensile strength ranging from 580 to 1650 MPa.

- Temperature Range: Operates effectively across a wide temperature spectrum, from high heat environments at 600°C to low temperatures as low as -253°C.

- Superior Corrosion Resistance: Possesses excellent resistance to corrosion.

- Non-Magnetic Nature: Exhibits non-magnetic properties.

- Low Thermal Conductivity: Demonstrates low thermal conductivity.

- Minimal Damping Resistance: Offers low damping resistance.

- Diverse Applications: Renowned for its high strength, corrosion resistance, favorable strength-to-weight ratio, ductility, ease of machining, versatility in surface treatment, and recyclability.

Common Surface Treatment Methods for Titanium

1. Electroplating

The purpose of electroplating on the surface of titanium alloy is to improve the adhesion, conductivity and brazing properties of titanium alloy;

However, it is difficult to plate chromium directly on titanium. Usually, nickel is plated first and then chromium is plated.

2. Nitriding:

Using chemical heat treatment technologies such as plasma nitriding, multi-arc ion plating, ion implantation and laser nitriding,

A golden yellow coating is formed on the surface of titanium, thereby improving the wear resistance, corrosion resistance and fatigue resistance of titanium.

3. Anodizing:

The anodizing technology of titanium is relatively easy. In some oxidizing media, under the action of applied voltage, the titanium anode can form a thick oxide film, thus improving its corrosion resistance, wear resistance and weather resistance.

4. Coloring:

Atmospheric oxidation and anodizing are used for surface coloring treatment to form a variety of colors on the surface and improve the aesthetic appearance.

5. Blue Surface:

The surface of the titanium alloy is oxidized at high temperatures to form a tough, corrosion-resistant oxide film, thereby improving the corrosion resistance and wear resistance of the titanium alloy and significantly improving its appearance quality.

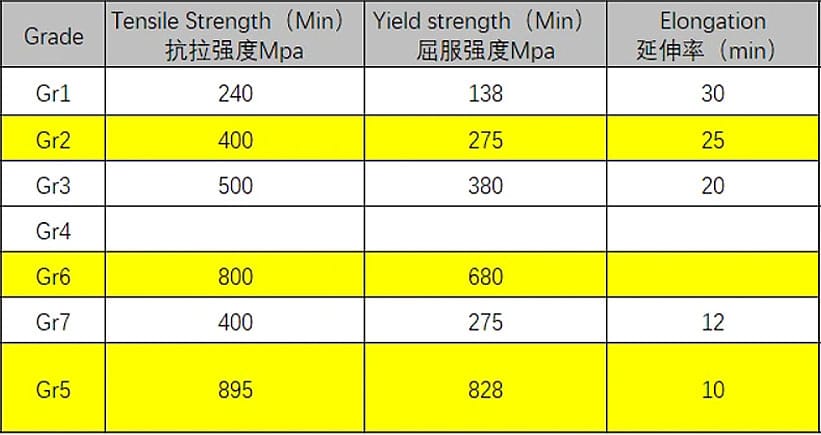

Comparison between Gr2 and Gr5

- Chemical composition: Gr2 contains 99% titanium and less than 0.2% carbon. In addition to titanium and carbon, Gr5 also contains manganese, vanadium, aluminum, tin and other components.

- Mechanical strength and tensile properties: Gr5 >Gr2.

- Corrosion resistance: Gr5 >Gr2 in acidic environment

- Processing and plate performance: Gr2>Gr5

- Weldability: Gr2>Gr5

- Price: Gr5>Gr2

Contact Information

Website: https://syzrodends.com

Email: [email protected]

Send Us a Message

Please submit the form or email to [email protected]