Rod Ends Manufacturing

High-Precision Rod Ends Manufacturing with Trusted Quality

35,000 sq. ft production facility

50+ advanced machines

Strict quality control system

20+ years engineering & production

Precision Rod Ends Manufacturing Backed by Experience

With 20+ years of experience, SYZ Machine delivers high-precision rod ends and mechanical parts worldwide.

Our 35,000㎡ facility includes CNC machining, turning, grinding, quality inspection, and final packaging zones.

Equipped with over 50 advanced machines, we handle both prototyping and large-scale production with speed and consistency.

We follow ISO 9001 standards and conduct dimensional, thread, hardness, and salt spray testing to ensure stable quality.

From off-road to automation industries, we’re your trusted engineering and manufacturing partner.

35,000 sq. ft production facility

50+ advanced machines

Strict quality control system

20+ years engineering & production

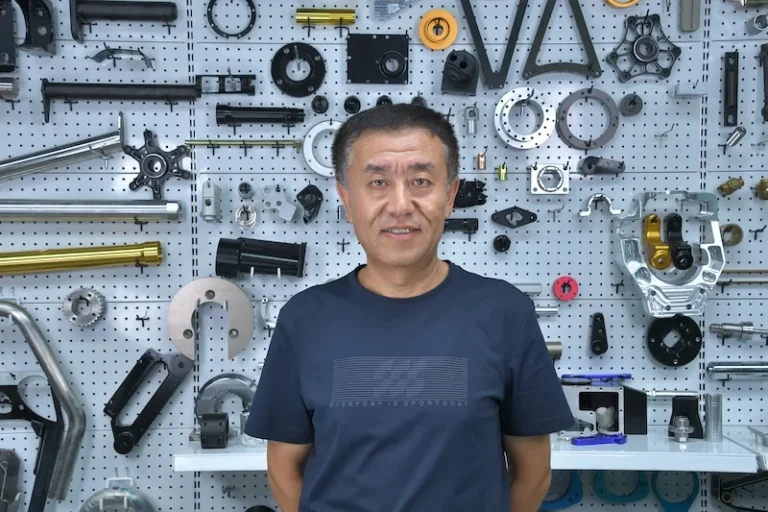

Technician Team

Jack Wang

Production Coordinator

I turn engineering drawings into deliverable products on time, every time. My job isn’t just to coordinate production, it’s to protect our clients’ trust.

Pei Zhou

Quality Manager

Precision doesn’t come from luck, it comes from experience and exact calculations. I make sure every rod end we design fits right and lasts longer.

How We Build Quality Into Every Step

Instead of only checking the final product, we embed quality into each step of our rod ends manufacturing process—from forging to final inspection.

Forging

STEP 1

Rough Machining

STEP 2

Drilling / Boring

STEP 3

Slot Punching

STEP 4

Finish Machining

STEP 5

Polishing Metal Surfaces

STEP 6

Shaft Grinding

STEP 7

External Thread Rolling

STEP 8

Tapping – Internal Thread

STEP 9

Press Fitting

STEP 10

Injection Molding

STEP 11

Torque Adjustment

STEP 12

Torque Testing

STEP 13

Inspection & Packaging

STEP 14

Custom Machining Service

Whether you need a standard-size rod end or a fully customized design, we are equipped to deliver precision solutions tailored to your specific application.

What We Offer

Drawings & Samples Accepted

Send us your technical drawings or physical samples—we’ll turn them into production-ready designs.

Multiple Materials Available

Choose from chromoly, stainless steel, aluminum, carbon steel, or even titanium depending on your performance requirements.

Thread Types & Directions

Metric or imperial, left-hand or right-hand—we manufacture to your specs.

Custom Structure & Size

Support for oversized joints, extended shanks, or special angles—built for your exact use case.

Flexible MOQ

Small-volume prototyping or mass production—we support both.

Engineering Support

Our experienced engineers assist with structure optimization, load calculations, and material selection.

Custom Solutions, Built for Performance

From design consultation to sampling, from machining to final inspection—our team ensures every custom rod end delivers both precision and durability.

FAQs About Rod Ends Manufacturing

1. Can you manufacture rod ends based on my technical drawings or samples?

Yes, we support custom production based on drawings or samples. We can manufacture according to your requirements for dimensions, tolerances, materials, thread direction, and ball structure.

2. What types of materials can you offer for rod ends?

We commonly work with Chromoly, Stainless Steel, Aluminum, Carbon Steel, and Titanium. We’ll recommend the best material based on your application needs.

3. Do you offer custom surface treatments or finishes?

Yes, we provide a wide range of finishes, including zinc plating, electrophoresis, anodizing, nickel plating, and phosphating to meet various corrosion resistance and appearance needs.

4. What’s your typical lead time for custom rod end orders?

Samples are usually ready within 7–12 days. Bulk production takes about 15–30 days depending on the complexity and order size.

5. Can you help with rod end design or structure optimization?

Absolutely. Our engineering team can provide advice on materials, structure, and load-bearing capacity to help balance performance and cost.

6. What testing do you perform to ensure product quality?

We conduct dimensional inspection, thread gauge checks, hardness testing, salt spray testing, and 100% visual inspection before shipment.

7. What is your minimum order quantity (MOQ) for custom rod ends?

Our MOQ is flexible. Some models support as low as 50–100 pcs. Send us your drawings and we’ll confirm based on process and cost.

8. Can I request a free sample before placing a bulk order?

Yes. We offer free samples for some standard sizes. For custom parts, sample cost may apply but can be refunded in bulk orders.

Knowledge

Need Technical Support?

Our experts offer fast response, design support, and product matching for your mechanical application.