Quality Control

We don’t just inspect quality at the end—we build it into every part, every step.

Quality is not just a final step—it’s our foundation

At SYZ Machine, quality starts at the source—not just at the final check.

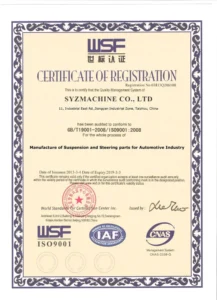

We follow a fully implemented ISO 9001 Quality Management System, with inspections from raw material to packaging.

Our lab is equipped with precision tools, thread gauges, hardness testers, and salt spray chambers for in-process and final checks.

Our experienced QA team works side-by-side with engineers to ensure dimensional accuracy, durability, and performance.

You receive more than compliant parts—you get reliable, specification-matched solutions built to perform.

Built-in Quality, Not Inspected In

ISO-Certified, Fully Traceable

From Threads to Salt Spray

Experienced Team, Proven Process

Built-in Quality, Not Inspected In

ISO-Certified, Fully Traceable

From Threads to Salt Spray

Experienced Team, Proven Process

Inspection Process to Ensure Quality

To ensure that every rod end meets our performance and durability standards, we conduct a series of thorough inspections throughout the manufacturing process.

Dimensional Inspection

All critical dimensions are checked using calibrated tools to ensure precise fit and compatibility.

Visual Inspection

Each part is visually inspected for defects, scratches, burrs, or deformation before assembly and packaging.

Radial Play / Torque Test

We measure radial clearance and rotational torque to ensure smooth movement and consistent joint tightness.

Thread Gauge Inspection

All threaded components are tested with go / no-go gauges to verify thread accuracy and compatibility.

Material Verification

Material composition is verified as needed to ensure the correct grade of steel or alloy is used.

Hardness Testing

Components are randomly tested for surface or core hardness to confirm heat treatment effectiveness.

Plating Thickness Check

Coating thickness is measured using specialized tools to ensure adequate corrosion protection.

Delivery & Warehousing Capability

We understand how important stable lead times and efficient shipping are for your business. That’s why we’ve built a responsive warehousing and delivery system to ensure your rod end orders arrive safely and on time.

Reliable Lead Time Control

Clear production planning & real-time tracking. Fast response for both samples and bulk orders

Warehouse Ready for Buffer Stock

Support customer buffer inventory for repeat orders. Suitable for long-term cooperation and blanket PO

Customized Packing Options

Cleaned, labeled, individually or bulk packed. Packaging meets export, retail, or assembly-line use

Global Shipping Coordination

Experienced logistics support team. Coordinate with your freight forwarder or use ours

Export Documents & Compliance

CO, Form E/F, MSDS, packing list, invoices, and more.

From Factory to Destination—Safe, Fast, and Dependable

Our delivery and warehousing system is built to meet the demands of global B2B customers. Whether you need just-in-time shipments or phased deliveries, we’re here to make it smooth.

Need Technical Support?

Our experts offer fast response, design support, and product matching for your mechanical application.