A spherical bearing, also known as a spherical plain bearing, spherical bushing, or spherical uniball bearing, is designed to accommodate angular motion and oscillating movements between two components. These bearings are built to handle misalignment, heavy loads, and extreme conditions, ensuring durability and reliable performance. Whether you’re in industrial or automotive applications, spherical bearings provide excellent load capacity and corrosion resistance, making them essential for machinery requiring flexibility and strength.

In this blog, we’ll dive deeper into what spherical bearings are, their structure, their materials, their features and their applications. Finally, we will also compare the differences between spherical bearings and spherical roller bearings.

Spherical Bearing Structure

A spherical bearing typically consists of three key components: the outer ring (or race), the inner ring (or ball), and the liner. Depending on their function, these bearings are categorized into two types, which we’ll explore in detail below.

Steel to Steel Spherical Bearing

Below is an image of our COM series steel to steel spherical bearing, which showcases the classic design of this bearing type.

Outer Ring (Race)

Sliding Surface (Liner)

Inner Ring (Ball)

Grease Zerk

This structure represents one of the earliest designs of spherical bearings. Around 1840, James Nasmyth first used the Self-aligning Plain Bearing to support drive shafts in factory machinery, and the original design was based on the steel to steel structure.

Due to the friction involved, steel to steel spherical bearings require lubrication. The housing is equipped with a grease zerk, which allows for the regular application of lubricating grease to maintain smooth operation and reduce wear.

Self-Lubrication Spherical Bearing

Below is an image of our SLB series self-lubrication spherical bearing, showcasing this advanced bearing type.

Outer Ring (Race)

Sliding Surface (Liner)

Inner Ring (Ball)

This bearing achieves self-lubrication by using specialized materials for the sliding surface, such as reinforced nylon, PTFE (or Teflon), or bronze. These materials help reduce friction and wear without the need for additional lubrication, making maintenance easier and more efficient. This design is particularly useful in applications where regular lubrication is challenging or not possible.

Spherical Bearing Materials

Depending on the application of the spherical bearing, different components are made from various materials to optimize performance. Here are the key materials used for each component:

Outer Ring Materials:

Alloy steel

Carbon steel

Stainless steel

52100 bearing steel

Sliding Surface Materials:

Steel-on-steel (no self-lubricating materials)

Reinforced nylon

PTFE (or Teflon)

Bronze mesh

Inner Ring Materials:

52100 bearing steel

Carbon steel

Stainless steel

These materials are chosen based on factors like load requirements, operating conditions, and whether self-lubrication is necessary.

Spherical Bearing Features

Angular Misalignment Compensation: Spherical bearings are designed to accommodate angular misalignment between the shaft and housing, allowing for smooth operation even when there is slight misalignment, preventing stress on the components.

High Load Carrying Capacity: With their robust design, spherical bearings can handle both radial and axial loads, making them ideal for high-load applications in industries such as automotive, construction, and manufacturing.

Suitable for Oscillating/Tilting Motion: These bearings are perfect for applications involving oscillating or tilting motions, providing reliable performance in machines where continuous or repetitive movement is required.

Spherical Bearing Applications

ATV / UTV

- Rear suspension pivot

- Shock absorber connection points

- Steering linkage joints

- Adjustable rod assemblies

Motorcycle

- Swing arm pivot

- Shock eye mounts (upper & lower)

- Steering stem joint

- Adjustable linkage mechanisms

Automotive / Motorsports

- Suspension system: Control arm, trailing arm, sway bar link

- Steering linkage: Tie rod end, steering rack joint

- Shock absorber mounts

- Transmission & drivetrain connection points

- Race car chassis and adjustable components

Construction & Heavy Machinery

- Boom linkage of excavators and loaders

- Hydraulic cylinder ends

- Linkage mechanisms for bulldozers, cranes, and wheel loaders

Aerospace / Defense

- Landing gear joints

- Flight control linkages

- Missile servo mechanisms and weapon mounting systems

Agricultural Equipment

- Tractor steering links

- Harvester linkages and suspension arm joints

- Sprayer and plow swing connections

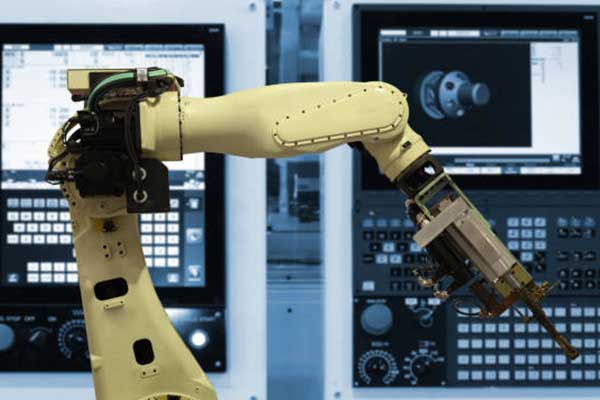

Industrial Equipment

- Robotic arm joints and automation mechanisms

- Swing components in packaging or conveyor systems

- Press machine and mold opening/closing linkages

- Support points in textile and printing machines

Energy & Industrial Systems

- Wind turbine yaw and pitch systems

- Valve actuator linkages in petrochemical equipment

- Natural gas valve control rods

- Seismic joints in building structures

These applications highlight the versatility and reliability of spherical bearings in a wide range of industries, ensuring smooth operation in high-load, high-performance environments.

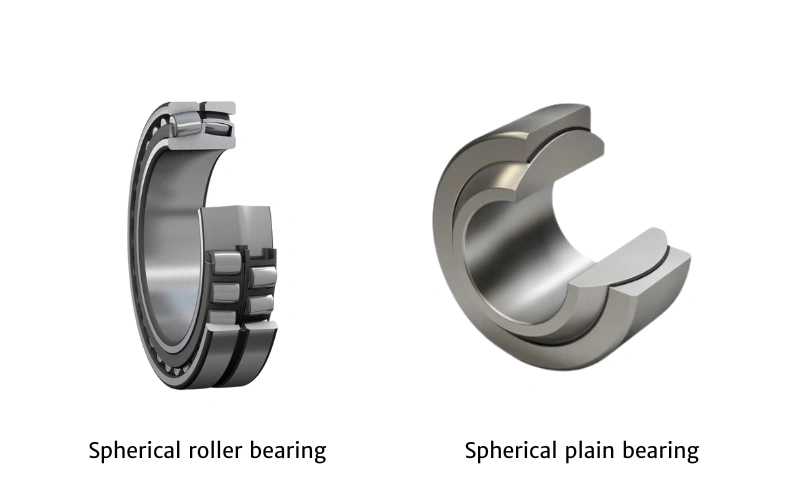

Difference Between Spherical Bearing and Spherical Roller Bearing

The core difference between a spherical bearing (also known as a spherical plain bearing) and a spherical roller bearing lies in their design. A spherical bearing uses sliding elements to reduce friction, while a spherical roller bearing uses rolling elements (such as cylindrical rollers) to carry the load. Below is a cross-sectional comparison of both bearings, clearly illustrating the difference between their components.

Conclusion

In summary, spherical bearings are versatile, offering solutions for misalignment, high loads, and oscillating movements. With their varied materials and applications across industries, these bearings provide durable and reliable performance in both industrial and automotive sectors.

If you’re looking to know details of our spherical bearing product specifications and transaction terms, check our spherical bearing buyer’s guide.