Introduction

In the world of modern agriculture, combine harvesters are indispensable machines, and their efficiency depends on how well all the parts work together. As someone who’s worked with these machines up close, I can tell you that rod ends—the spherical bearings that act as joints and connectors—are critical to keeping everything running smoothly. They play a pivotal role in several systems of the harvester, ensuring that the machine performs efficiently under varying conditions. From adjusting the reel to fine-tuning the concave gap in the threshing system, or precisely controlling the grate position in the separation system, rod ends provide the strength and flexibility needed for reliable operation.

In this article, I’ll walk you through three key applications of rod ends in combine harvesters, showing how they contribute to better performance and reliability in real-world harvesting conditions.

1. Reel System

Understanding the Application

- What It Does: The reel’s job is to guide the crop—whether standing or lodged—into the cutting knives and feed it into the auger. It’s an essential part of the feeding system.

- How It Works: To prevent crop wrap and ensure the correct feeding angle, modern reels use an eccentric mechanism to adjust the pitch of the tines (the bars that push the crop).

How Rod Ends Fit In

Where They Are Used:

- The eccentric control linkage connects the central eccentric disk (spider/cam) to each tine bar.

- The hydraulic push rod end is used to adjust the reel’s fore-aft position and height.

What Rod Ends Do:

- Handling Complex Motion: As the reel turns, the rod end lets the tine bars independently adjust their angles relative to the main shaft. This means the tines stay vertical as they enter the crop, and then tilt back to release the crop as the reel rotates.

- Dust and Wear Resistance: The reel operates directly in the crop canopy, so rod ends have to withstand the dust, debris, and wear from constant contact with crops. They must be designed to handle that environment without failing or seizing up.

2. Threshing System

Understanding the Application

- What It Does: The concave sits just below the threshing drum, and its gap with the drum is crucial for the threshing process. If the gap is too small, you get a lot of broken grain. Too wide, and you don’t get proper threshing.

- How It Works: In the image below, you can see a hydraulic/electric push rod connected to a complex linkage system used to lift and adjust the heavy concave.

How Rod Ends Fit In

Where They Are Used:

The rod end connects the linear actuator (hydraulic cylinder) to the concave support rockshaft.

What Rod Ends Do:

- Converting Linear to Arc Motion: The actuator moves in a straight line, but the concave usually adjusts along an arc to stay concentric with the drum. The rod end allows the push rod and rockshaft to form a precise angle without binding, ensuring smooth motion.

- Withstanding High Loads: The concave bears a lot of pressure from the crop flow during threshing. The rod end isn’t just for adjustment—it’s also a load-bearing component. It locks the position and resists the force generated by the crop flow, ensuring that the concave stays in place without drifting.

3. Separation System

Understanding the Application

- What It Does: The beater, located after the threshing drum, is responsible for throwing the threshed straw into the separation device (such as a stripper or separation rotor). The grate beneath it controls the separation efficiency.

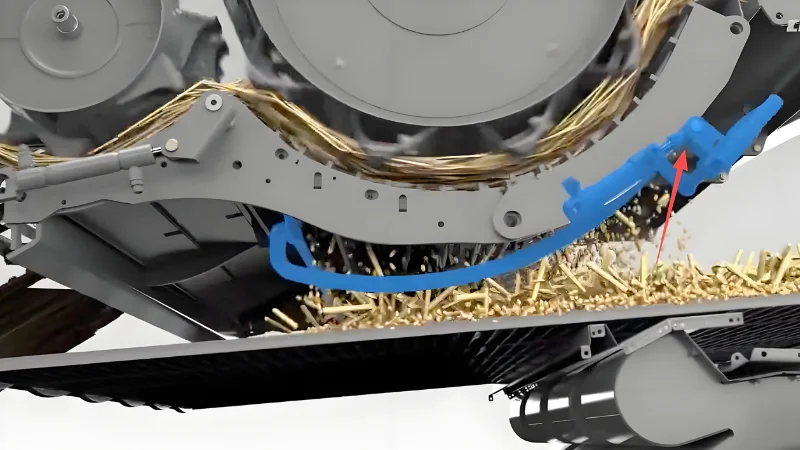

- How It Works: In the image below, the blue-highlighted area shows a typical multi-linkage adjustment system. Unlike the old manual bolt systems, this one actively adjusts.

How Rod Ends Fit In

Where They Are Used:

The red arrow in the image above points to the linkage drive end, which connects the main control rod to the grate frame.

What Rod Ends Do:

- Multi-Point Synchronized Linkage: To ensure the grate rises and falls evenly, the linkage system drives both ends of the grate simultaneously. The rod end acts as the pivot point for the linkage, eliminating installation errors and ensuring that the grate moves smoothly without misalignment or jamming.

- Geometric Adaptability: When the operator adjusts the grate from the cabin (to adapt to wet or dry crops), the rod end absorbs any non-axial forces in the linkage, ensuring that force is only transmitted along the linkage axis. This protects the actuator from bending and ensures precise movement.

Summary

In the end, it’s clear that rod ends are essential to the smooth operation of combine harvesters. From the reel system to the threshing and separation systems, rod ends are more than just connectors—they’re key components that ensure flexibility, precision, and durability in every aspect of the harvester’s work. I’ve seen firsthand how important these little parts can be, not just for keeping the machine running, but for maintaining its efficiency and longevity. As agricultural machinery continues to evolve, the role of rod ends will only expand, and I’m sure that we’ll see even more innovative uses for rod ends in agricultural area.