Weld On Ball Joint Specification Overview

| Specification | Value | Features |

|---|---|---|

| Ball I.D. | 10–80 mm / Custom | Precision-machined inner race |

| Housing O.D. | 20–120 mm / Custom | Outer ring with spherical surface |

| Material | Bearing Steel / Carbon Steel | High-strength bearing steel or carbon steel, surface treated for corrosion resistance |

| Greasing | Grease groove & hole | Refuelable design to extend service life |

| Misalignment Angle | ±5° ~ ±15° | Adjustable centering function to absorb deviation and prevent jamming |

| Finish | Zinc Black Oxide Chrome | Rust-proof and corrosion-resistant |

| Operating Temp. | -30°C to +120°C | Suitable for various working conditions |

| Type | GE..E / GE..ES / GE..LO... | A variety of structures are available to meet your needs |

Our Weld On Ball Joint Series

We understand the challenges you face when sourcing rod ends. We are not just a supplier; we are your partner, dedicated to solving your most critical concerns.

SYZ-HSB

Heavy-duty Spherical Bearing

Large-size, high-load design, commonly used in hydraulic cylinder ends and vibration arm structures.

SYZ-RHA

Rod-End Housing Assembly

Provides greater misalignment capability, suitable for vibration-intensive and offset motion joints; built-in spherical plain bearing enables reliable rotary connections.

SYZ-WBJ

Weldable Bearing Joint

Serviceable design with replaceable bushing and ball surface; bearing integrated with welding sleeve for structural weld points.

Weld On Ball Socket Size Chart

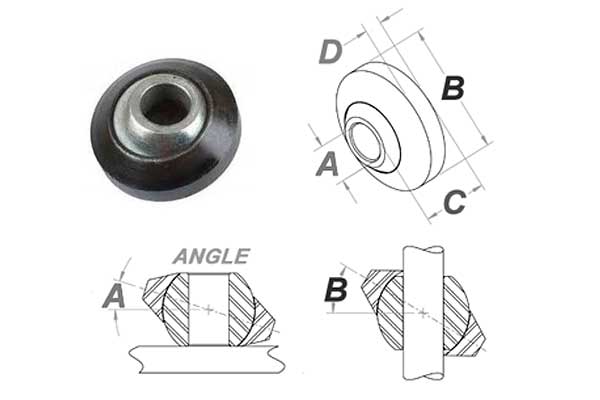

SYZ-HSB Shoulder Design

| Series ID | A (Ball Dir.) | B (O.D.) | C (Ball Width) | D (Housing Width in.) | Angle A (°) | Angle B (°) | |

|---|---|---|---|---|---|---|---|

| SYZ-HSB-S001 | 0.75 | 2 | 1.75 | 3/8 | 17° | 0° | |

| SYZ-HSB-S002 | 0.75 | 2.25 | 1.75 | 3/8 | 15° | 0° | |

| SYZ-HSB-S003 | 1.25 | 3.5 | 2 | 1/2 | 20° | 0° | |

| SYZ-HSB-S004 | 1.25 | 4 | 2 | 5/8 | 18° | 0° |

SYZ-HSB No Shoulder Design

| Series ID | A (Ball Dir.) | B (O.D.) | C (Ball Width) | D (Housing Width in.) | Angle A (°) | Angle B (°) | |

|---|---|---|---|---|---|---|---|

| SYZ-HSB-NS001 | 0.5 | 2 | 1 | 3/8 | 11° | 40° | |

| SYZ-HSB-NS002 | 0.62 | 2 | 1 | 3/8 | 11° | 33° | |

| SYZ-HSB-NS003 | 0.62 | 2.25 | 1 | 3/8 | 10° | 35° | |

| SYZ-HSB-NS004 | 0.75 | 2 | 1 | 3/8 | 11° | 26° | |

| SYZ-HSB-NS005 | 0.75 | 2.25 | 1 | 3/8 | 10° | 28° | |

| SYZ-HSB-NS006 | 0.75 | 2.25 | 1.38 | 9/16 | 17° | 30° | |

| SYZ-HSB-NS007 | 0.75 | 2.5 | 1.38 | 3/8 | 17° | 32° | |

| SYZ-HSB-NS008 | 0.87 | 2.25 | 1.38 | 9/16 | 17° | 27° | |

| SYZ-HSB-NS009 | 0.87 | 2.5 | 1.38 | 3/8 | 17° | 26° | |

| SYZ-HSB-NS010 | 1 | 2 | 1 | 3/8 | 11° | 17° | |

| SYZ-HSB-NS011 | 1 | 2.25 | 1 | 3/8 | 10° | 19° | |

| SYZ-HSB-NS012 | 1 | 2.75 | 1.75 | 7/8 | 17° | 26° | |

| SYZ-HSB-NS013 | 1 | 3.12 | 1.75 | 9/16 | 15° | 31° | |

| SYZ-HSB-NS014 | 1.12 | 2.75 | 1.38 | 11/16 | 10° | 30° | |

| SYZ-HSB-NS015 | 1.12 | 2.75 | 1.75 | 13/16 | 17° | 28° | |

| SYZ-HSB-NS016 | 1.12 | 3.12 | 1.38 | 3/8 | 11° | 32° | |

| SYZ-HSB-NS017 | 1.12 | 3.12 | 1.75 | 9/16 | 15° | 25° | |

| SYZ-HSB-NS018 | 1.25 | 2.75 | 1.75 | 7/8 | 17° | 25° | |

| SYZ-HSB-NS019 | 1.25 | 3.12 | 1.75 | 9/16 | 15° | 24° | |

| SYZ-HSB-NS020 | 1.43 | 3.5 | 1.75 | 1/2 | 13° | 24° | |

| SYZ-HSB-NS021 | 1.43 | 3.5 | 1.75 | 1/2 | 13° | 23° | |

| SYZ-HSB-NS022 | 1.43 | 4 | 1.75 | 5/8 | 13° | 23° | |

| SYZ-HSB-NS023 | 1.5 | 4.5 | 2.5 | 1 | 20° | 33° | |

| SYZ-HSB-NS024 | 1.75 | 4.5 | 2.5 | 11/16 | 20° | 28° | |

| SYZ-HSB-NS025 | 2 | 4.5 | 2.25 | 1 | 14° | 22° |

Customization Services

Materials & Surface Finish

- GCr15 / 52100 Bearing Steel provides high hardness and fatigue resistance, ideal for bearing balls and inner races.

- Carbon Steel Housing is cost-effective and strong, suitable for large support structures.

- Zinc Coating offers economical rust protection for general-purpose use.

- Black Oxide adds aesthetic appeal and corrosion resistance for medium-level environments.

- Chrome Plating delivers superior corrosion resistance for premium projects and high-humidity conditions.

Customization Options

- Dimensions can be tailored based on customer drawings, with full 3D modeling support.

- Surface Finishes such as zinc, e-coating, or painting meet diverse aesthetic and environmental requirements.

- Packaging options include kraft boxes, poly bags, or color boxes, with customizable logos and barcodes.

- Logo can be applied via laser, etching, or engraving, supporting OEM branding services.

- Structures are available in single, split, or serviceable designs, customized to your specific application needs.

- Logo can be applied via laser, etching, or engraving, supporting OEM branding services.

Need Help with Your Project?

Where Our Products Fit Best

Cylinder Ends

Excavators, Bulldozers, Harvesters, Forklifts

Heavy-Duty Equipment

Construction Vehicles, Transport Trucks, Lifting Equipment

Rod & Arm Linkage

Mining Machinery, Loaders, Vibratory Compactors

Agricultural Joints

Tractors, Lawn Mowers, Crop Protection Machinery

Shock-Absorbing

Railway Equipment, Forestry Machinery, Military Engineering Vehicles

More Related Products

We offer a comprehensive range of products to meet your specific application needs. Filter by application to find your solution.

Design: Metal to Metal

Models: COM

Material: 4130 Chromoly Steel Race and 52100 Bearing Steel Ball

Size: Both Inch and Metric Size Available

Design: Metal to Metal

Models: COM-T

Material: 4130 Chromoly Steel Race and 52100 Bearing Steel Ball

Size: Both Inch and Metric Size Available

Design: Metal to Metal

Models: COM-SS

Material: 304/316 Stainless Steel Race and 440C Stainless Steel Ball, 17-4ph Optional

Size: Inch Size Available

Design: Load Slot

Models: SLB

Material: 4130 Chromoly Steel Race and 52100 Bearing Steel Ball and Nylon Race with PTFE

Size: Inch Size Available

Design: High Misalignment

Models: YPB-T

Material: 4130 Chromoly Steel Race and 52100 Bearing Steel Ball and Teflon Lined

Size: Inch Size Available

Design: Wide Series

Models: WPB-T WPB-TG (with Staking Groove)

Material: 4130 Chromoly Steel Race and 52100 Bearing Steel Ball, Stainless Steel Optional

Size: Inch Size Available

Design: Self-lubricating

Models: GEC

Material: Carbon Steel Race and 52100 Bearing Steel Ball

Size: Metric Size Available

Design: Heavy Duty

Models: GEZ, GEZ-2RS(with Rubber Seals)

Material: 52100 Bearing Steel Race and Ball

Size: Metric Size Available

Model: CS (DIN71802)

Type: Gas Spring Ball Joint, Sealing Cap Optional

Material: Carbon Steel, Stainless Steel Optional

Size: Metric Size Available

Model: AI (GN71802.1)

Type: Inline Ball Joint, Sealing Cap Optional

Material: Carbon Steel, Stainless Steel Optional

Size: Metric Size Available

Model: QD

Type: Quick Relese Ball Joint

Material: Carbon Steel, Stainless Steel or Aluminum Optional

Size: Inch Size Available

Model: QI

Type: Quick Disconnect Ball Joint

Material: Carbon Steel, Stainless Steel Optional

Size: Inch Size Available

Model: ES

Type: Staked Ball Joint with Rubber Grommet

Material: Carbon Steel, Stainless Steel Optional

Size: Inch Size Available

Model: DIN71803

Type: Ball Stud/Ball Pin

Material: Carbon Steel, Stainless Steel Optional

Size: Base on Your Request

Model: DIN71805

Type: Ball Socket Steel

Material: Carbon Steel, Stainless Steel Optional

Size: Base on Your Request

Structure: Loader Slot Heavy Duty

Models: XM(Male Thread) / XF(Female Thread)

Material: 4130 Chromoly Steel

Bore: 0.1900~2.0000

Thread: 10-32~2-12 Inch

Static Load: 2,851~225,924 lbs

Structure: Loader Slot Offset

Models: XM-OS(Male Thread)

Material: 4130 Chromoly Steel

Bore: 0.7500~0.8750

Thread: 3/4-16,7/8-14 Inch

Structure: 3-Piece Offset

Models: JMX-OS(Male Thread)

Material: 4130 Chromoly Steel

Bore: 0.7500~0.8750

Thread: 7/8-14 Inch

Structure: Loader Slot Heavy Duty

Models: AM(Male Thread) / AF(Female Thread)

Material: Aluminum

Bore: 0.1900~1.0000

Thread: 10-32~1-14 Inch

Static Load: 788~36,285 lbs

Structure: Loader Slot Heavy Duty

Models: EXM(Male Thread) / EXF(Female Thread)

Material: Carbon Steel

Bore: 0.1900~1.0000

Thread: 10-32~1-12 Inch

Static Load: 1,169~43,541 lbs

Structure: 2-Piece Commercial Industrial

Models: CM-T(Male Thread) / CF-T(Female Thread)

Material: Carbon Steel

Bore: 0.1250~1.0000

Thread: 10-32~1 1/4-12 Inch

Static Load: 700~16,922 lbs

Structure: 2-Piece Commercial Industrial

Models: SCM-T(Male Thread) / SCF-T(Female Thread)

Material: Stainless Steel

Bore: 0.1900~1.0000

Thread: 10-32~1 1/4-12 Inch

Static Load: 1,190~11,595 lbs

Structure: 2-Piece Commercial Industrial

Models: PCM(-T)(Male Thread)

Material: 4130 Chromoly Steel

Bore: 0.3750~0.7500

Thread: 3/8-24~3/4-16 Inch

Static Load: 9,088~27,000 lbs

Structure: 2-Piece Commercial Industrial

Models: PCYM-T(Male Thread) / PCYF-T(Female Thread)

Material: 4130 Chromoly Steel

Bore: 0.3750~0.7500

Thread: 3/8-24~3/4-16 Inch

Static Load: 11,050~30,290 lbs

Structure: 3-Piece Precision

Models: JMX(-T)(Male Thread) / JFX(-T)(Female Thread)

Material: 4130 Chromoly Steel

Bore: 0.1900~1.2500

Thread: 10-32~1 1/4-12 Inch

Static Load: 2,851~138,800 lbs

Structure: 3-Piece Precision

Models: HJMX(-T)(Male Thread)

Material: 4130 Chromoly Steel

Bore: 0.3750~0.7500

Thread: 3/8-24~3/4-16 Inch

Static Load: 11,410~44,650 lbs

Structure: 3-Piece Precision

Models: ALJM(-T)/ALRSM(-T)(Male Thread) / ALJF(-T)(Female Thread)

Material: Aluminum

Bore: 0.1900~0.7500

Thread: 10-32~3/4-16 Inch

Static Load: 1,360~23,390 lbs

Structure: 3-Piece Precision

Models: JM(-T)(Male Thread) / JF(-T)(Female Thread)

Material: Carbon Steel

Bore: 0.1250~1.2500

Thread: 10-32~1 1/4-20 Inch

Static Load: 500~43,555 lbs

Structure: 3-Piece Precision

Models: VM(Male Thread) / VF(Female Thread)

Material: Carbon Steel

Bore: 0.1900~0.7500

Thread: 10-32~3/4-16 Inch

Static Load: 1,169~11,518 lbs

Structure: Injection Molded

Models: PM(Male Thread) / PF(Female Thread)

Material: Carbon Steel

Bore: 0.1900~0.7500

Thread: 10-32~3/4-16 Inch

Static Load: 1,174~10,937 lbs

Design: Studded

Material: 4130 Chromoly Steel / Carbon / Stainless Steel / Aluminum

Thread: Male / Female, LH / RH

Size: Inch / Metric

Need Help with Your Project?

About SYZ ROD ENDS

With over 26 years of expertise in the weld-on ball joint sector, we specialize in delivering durable and reliable solutions for heavy-duty connection and motion applications. Our 35,000 sq ft ISO 9001-certified facility is equipped with advanced CNC machinery, heat treatment lines, and automated inspection systems, ensuring every weld-on ball joint meets the highest performance and safety standards.

Engineering & Design Support

Your Partner in Innovation

Accelerate your product development with our complete engineering resources. From concept to validation, we provide the technical data and files you need to integrate seamlessly and design with confidence.

Comprehensive PDF Datasheets / 3D STEP Files for instant CAD integration / 2D CAD Drawings (DWG, DXF) for precision detailing

OEM / ODM Customization

From Concept to Global Delivery

Requirement Analysis-Define application, performance metrics, and target cost

Engineering Design & 3D Modeling- Transform ideas into CAD drawings and 3D models

Prototyping & Validation-Rapid prototyping and testing for design accuracy

Tooling & Mass Production-From approved samples to large-scale manufacturing

Quality Assurance-Rigorous inspections for consistent performance

Packaging & Services

Beyond Products, We Deliver Value

We ensure your products arrive safe, secure, and ready for market. From professional standard packaging to fully customized solutions, our services are designed to support your brand on a global scale.

White-label box packaging for a clean, brand-ready look / Multi-language manuals for global users / Tailored solutions with reliable worldwide logistics support

FAQ

What is your lead time?

We offer flexible lead times. For standard products, the lead time is typically 3-4 weeks. For custom products, depending on the complexity of the order, the lead time may take 4-6 weeks. If you have urgent needs, please inform us at the time of ordering, and we will do our best to expedite the process.

For urgent orders, we can reduce the lead time to 2-3 weeks, but additional rush fees may apply.

How is the price of custom products calculated?

The pricing for custom products is determined by the following factors:

Size and specifications: Larger or more complex sizes will increase the price.

Material selection: High-strength materials or special surface treatments may increase costs.

Quantity: Bulk orders typically receive more competitive pricing.

Lead time: Rush orders may incur additional fees.

We recommend providing specific requirements so that we can offer a detailed quotation.

What is the quality assurance for custom products?

All custom products undergo strict quality control to meet international standards and your specific requirements. We conduct multiple inspections throughout the production process to ensure every step meets quality standards. We offer a 12-month warranty, and if any quality issues arise under normal use, we will provide replacement or repair services free of charge.

How can I track the progress of my order?

Once your order is confirmed and enters production, we will provide regular production progress updates. You can contact our customer service team via email or phone to get the latest status and delivery information.

How do you ensure product quality?

We have strict quality control processes in place, from raw material sourcing, production, to final product inspection. All products undergo 100% quality inspection before leaving the factory to ensure defect-free products.

How do I place an order?

You can place an order by:

Contacting our sales team directly: Provide your requirements or design drawings, and we will prepare a quotation and lead time for you.

Submitting your order online: Submit your request through our website, and we will reply within 24 hours.