Clevis Rod Ends | Clevis Joints

25+ Experienced Manufacturer, Your Trusted Clevis Partner for Standard and Custom Solutions.

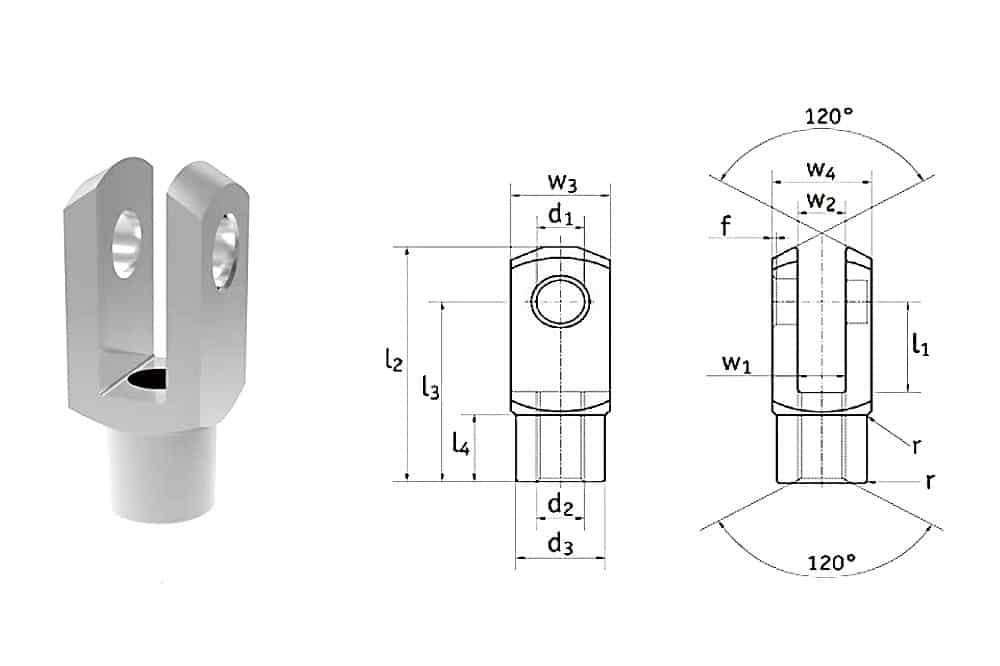

- DIN 71752 G Series

- CR CL Series

- Custom Clevis Rod Ends

About Us

SYZ Machine is a leading machinery components manufacturer in China, our main products are clevis rod ends, rod ends, ball joints, spherical plain bearing, cnc maching parts and etc. We have a wide range of clevis joints for automotive, pneumatics, electricity, aerospace applications. Custom service is available for your exact request, such as material changing and female and male clevis ends with right or left hand threads. Our most popular clevis joints are DIN 71752 G series and CR/CL series with standard sizes from M4 to M48 in Metric and 5-16/24, 3/8-24, 1/2-20, 5/8-18, 3/4-16 in inch. For more details, please check below information and send your inquiry to get a reply in 24hrs.

Popular Clevis Rod Ends

Hot Selling Design and Size Chart

DIN 71752 G series Clevis Joints

Material: Carbon Steel/Stainless Steel and Aluminum Optional

Surface Treatment: Zinc Plating

Type1: With Clevis Pin, Washer, Cotter Pin Optional

Type2: With Clevis Spring Pin Optional

Thread: Female with Right or Left Hand

| Part NO. | THREAD d2 | d1 H9 | l1 | w3 | w4 | w1 | w2 | d3 | l2 | l3 | l4 | Approx Weight (Gram) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G 4x8 | M4 | 4 | 8 | 8 | 8 | 4 | 4 | 8 | 21 | 16 | 6 | 5 |

| G 4x16 | M4 | 4 | 16 | 8 | 8 | 4 | 4 | 8 | 29 | 24 | 6 | 7 |

| G 5x10 | M5 | 5 | 10 | 10 | 10 | 5 | 5 | 9 | 26 | 20 | 7.5 | 9 |

| G 5x20 | M5 | 5 | 20 | 10 | 10 | 5 | 5 | 9 | 36 | 30 | 7.5 | 13 |

| G 6x12 | M6 | 6 | 12 | 12 | 12 | 6 | 6 | 10 | 31 | 24 | 9 | 15 |

| G 6x24 | M6 | 6 | 24 | 12 | 12 | 6 | 6 | 10 | 43 | 36 | 12 | 21 |

| G 8x16 | M8 | 8 | 16 | 16 | 16 | 8 | 8 | 14 | 42 | 32 | 12 | 37 |

| G 8x16FG | M8x1 | 8 | 16 | 16 | 16 | 8 | 8 | 14 | 42 | 32 | 12 | 37 |

| G 8x32 | M8 | 8 | 32 | 16 | 16 | 8 | 8 | 14 | 58 | 48 | 12 | 54 |

| G 8x32FG | M8x1 | 8 | 32 | 16 | 16 | 8 | 8 | 14 | 58 | 48 | 12 | 54 |

| G 10x20 | M10 | 10 | 20 | 20 | 20 | 10 | 10 | 18 | 52 | 40 | 15 | 74 |

| G 10x20FG | M10x1.25 | 10 | 20 | 20 | 20 | 10 | 10 | 18 | 52 | 40 | 15 | 74 |

| G 10x40 | M10 | 10 | 40 | 20 | 20 | 10 | 10 | 18 | 72 | 60 | 15 | 116 |

| G 10x40FG | M10x1.25 | 10 | 40 | 20 | 20 | 10 | 10 | 18 | 72 | 60 | 15 | 116 |

| G 12x24 | M12 | 12 | 24 | 24 | 24 | 12 | 12 | 20 | 62 | 48 | 15 | 121 |

| G 12x24FG | M12x1.25 | 12 | 24 | 24 | 24 | 12 | 12 | 20 | 62 | 48 | 15 | 121 |

| G 12x48 | M12 | 12 | 48 | 24 | 24 | 12 | 12 | 20 | 86 | 72 | 18 | 175 |

| G 12x48FG | M12x1.25 | 12 | 48 | 24 | 24 | 12 | 12 | 20 | 86 | 72 | 18 | 175 |

| G 14x28 | M14 | 14 | 28 | 27 | 27 | 14 | 14 | 24 | 72 | 56 | 22.5 | 178 |

| G 14x28FG | M14x1.5 | 14 | 28 | 27 | 27 | 14 | 14 | 24 | 72 | 56 | 22.5 | 178 |

| G 14x56 | M14 | 14 | 56 | 27 | 27 | 14 | 14 | 24 | 101 | 85 | 22.5 | 258 |

| G 14x56FG | M14x1.5 | 14 | 56 | 27 | 27 | 14 | 14 | 24 | 101 | 85 | 22.5 | 258 |

| G 16x32 | M16 | 16 | 32 | 32 | 32 | 16 | 16 | 26 | 83 | 64 | 24 | 282 |

| G 16x32FG | M16x1.5 | 16 | 32 | 32 | 32 | 16 | 16 | 26 | 83 | 64 | 24 | 282 |

| G 16x64 | M16 | 16 | 64 | 32 | 32 | 16 | 16 | 26 | 115 | 96 | 24 | 411 |

| G 16x64FG | M16x1.5 | 16 | 64 | 32 | 32 | 16 | 16 | 26 | 115 | 96 | 24 | 411 |

| G 18x36 | M18 | 18 | 36 | 36 | 36 | 18 | 18 | 30 | 94 | 72 | 27 | 390 |

| G 18x36FG | M18x1.5 | 18 | 36 | 36 | 36 | 18 | 18 | 30 | 94 | 72 | 27 | 390 |

| G 20x40 | M20 | 20 | 40 | 40 | 40 | 20 | 20 | 34 | 105 | 80 | 30 | 550 |

| G 20x40FG | M20x1.5 | 20 | 40 | 40 | 40 | 20 | 20 | 34 | 105 | 80 | 30 | 550 |

| G 20x80 | M20 | 20 | 80 | 40 | 40 | 20 | 20 | 34 | 145 | 120 | 30 | 800 |

| G 20x80FG | M20x1.5 | 20 | 80 | 40 | 40 | 20 | 20 | 34 | 145 | 120 | 30 | 800 |

| G 25x50 | M24 | 25 | 50 | 50 | 50 | 25 | 25 | 42 | 132 | 100 | 36 | 1100 |

| G 25x50FG | M24x2 | 25 | 50 | 50 | 50 | 25 | 25 | 42 | 132 | 100 | 36 | 1100 |

| G 28x56 | M27 | 28 | 56 | 55 | 55 | 28 | 28 | 48 | 148 | 112 | 40 | 1500 |

| G 28x56FG | M27x2 | 28 | 56 | 55 | 55 | 28 | 28 | 48 | 148 | 112 | 40 | 1500 |

| G 30x54FG | M27x2 | 30 | 54 | 55 | 55 | 30 | 30 | 48 | 148 | 110 | 40 | 1440 |

| G 30x60 | M30 | 30 | 60 | 60 | 60 | 30 | 30 | 52 | 160 | 120 | 42 | 1970 |

| G 30x60FG | M30x2 | 30 | 60 | 60 | 60 | 30 | 30 | 52 | 160 | 120 | 42 | 1970 |

| G 35x54FG | M36x2 | 35 | 54 | 70 | 70 | 35 | 35 | 60 | 188 | 144 | 54 | 2930 |

| G 35x72 | M36 | 35 | 72 | 70 | 70 | 35 | 35 | 60 | 188 | 144 | 54 | 2930 |

| G 35x72FG | M36x2 | 35 | 72 | 70 | 70 | 35 | 35 | 60 | 188 | 144 | 54 | 2930 |

| G 36x72 | M36 | 36 | 72 | 70 | 70 | 36 | 36 | 60 | 188 | 144 | 54 | 2930 |

| G 36x72FG | M36x2 | 36 | 72 | 70 | 70 | 36 | 36 | 60 | 188 | 144 | 54 | 2930 |

| G 40x84FG | M42x2 | 42 | 84 | 85 | 85 | 40 | 40 | 70 | 232 | 168 | 63.5 | 5640 |

| G 42x84 | M42 | 42 | 84 | 85 | 85 | 42 | 42 | 70 | 232 | 168 | 63.5 | 5340 |

| G 42x84FG | M42x2 | 42 | 84 | 85 | 85 | 42 | 42 | 70 | 232 | 168 | 63.5 | 5340 |

| G 50x96 | M48 | 50 | 96 | 96 | 96 | 50 | 50 | 82 | 265 | 192 | 73 | 7860 |

| G 50x96FG | M48x2 | 50 | 96 | 96 | 96 | 50 | 50 | 82 | 265 | 192 | 73 | 7860 |

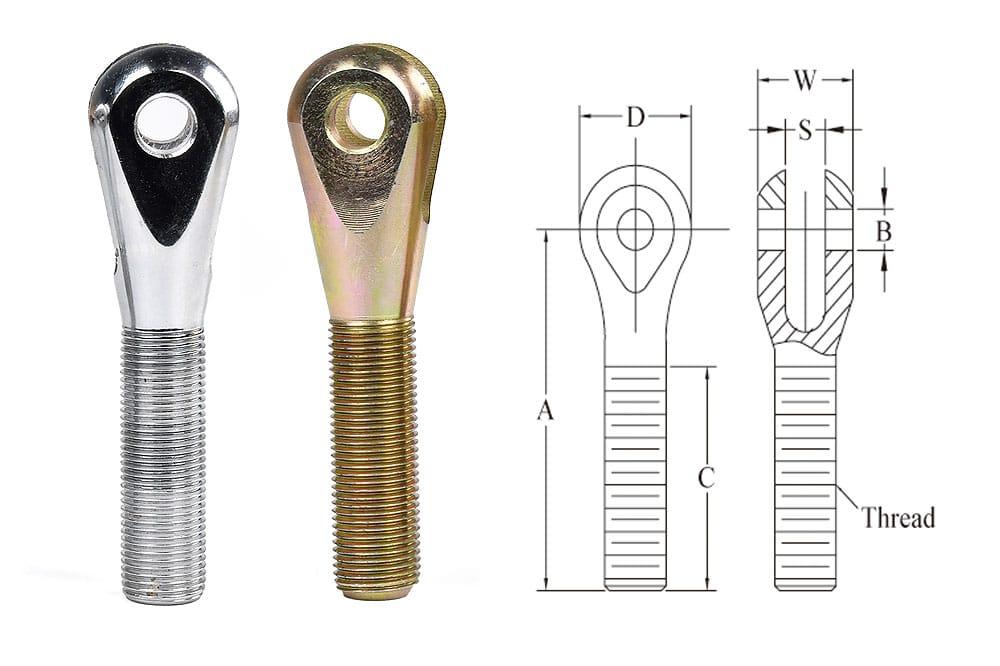

CR CL Series Clevis Rod Ends

Material: Carbon Steel/Stainless Steel Optional

Surface Treatment: Zinc Plating Polished/ Hard Chrome Plating

| Part Number Right Hand | Part Number Left Hand | Thread Male 3A REF | B DIA. +.005 -.000 | D DIA. +.010 -.010 | W Width +.005 -.005 | S Width +.005 -.005 | A Length +.015 -.015 | C Length +.062 -.031 |

|---|---|---|---|---|---|---|---|---|

| CR4-5 | CL4-5 | 5/16-24 | 0.25 | 0.875 | 0.625 | 0.188 | 2.25 | 1.25 |

| CR5-5 | CL5-5 | 5/16-24 | 0.3125 | 0.875 | 0.625 | 0.188 | 2.25 | 1.25 |

| CR5-6 | CL5-6 | 3/8-24 | 0.3125 | 0.875 | 0.625 | 0.188 | 2.25 | 1.5 |

| CR5-8 | CL5-8 | 1/2-20 | 0.3125 | 1 | 0.75 | 0.25 | 2.5 | 1.5 |

| CR6-8 | CL6-8 | 1/2-20 | 0.375 | 1 | 0.75 | 0.25 | 2.5 | 2 |

| CR6-10 | CL6-10 | 5/8-18 | 0.375 | 1.125 | 0.825 | 0.375 | 3.375 | 2 |

| CR6-12 | CL6-12 | 3/4-16 | 0.5 | 1.125 | 0.825 | 0.375 | 3.375 | 2 |

| CR7-8 | CL7-8 | 1/2-20 | 0.4375 | 1.125 | 0.825 | 0.375 | 3.375 | 2 |

| CR7-10 | CL7-10 | 5/8-18 | 0.4375 | 1.125 | 0.825 | 0.375 | 3.375 | 2 |

| CR8-10 | CL8-10 | 5/8-18 | 0.5 | 1.125 | 0.825 | 0.375 | 3.375 | 2 |

| CR8-12 | CL8-12 | 3/4-16 | 0.5 | 1.125 | 0.825 | 0.375 | 3.375 | 2 |

| CR8-12-1 | CL8-12-1 | 3/4-16 | 0.5 | 1.125 | 0.825 | 0.375 | 3.375 | 2 |

More Clevis Rod Ends / Clevis Joints

Buggy Clevis Limit Strap Clevis

Material: Carbon Steel

Surface: Yellow Zinc Plating

Dimension: In Inch

Legend Car Clevis

A-arm Clevis

Material: 4130 Chromoly Steel

Surface: Blackening

Dimension: In Inch

Weld-in Clevis

Material: 4130 Chromoly Steel/Carbon Steel/Titanium

Surface: Original

Dimension: In Inch or Metric

Clevis Rod End Male

Material: Stainless Steel

Surface: Original Raw Material

Dimension: In Inch or Millimeters

Clevis Bracket

Material: Carbon Steel

Surface: Powder Coating

Dimension: In Inch or Millimeters

Forged Yoke End

Material: Carbon Steel

Surface: White Zinc Plating

Dimension: In Inch or Millimeters

Steering Clevis

Material: Customized

Surface: Customized

Dimension: Customized

Agricultural Clevis

Material: Forged Steel

Surface: Plain / Self-Color

Dimension: In Inch or Millimeters

Steering Rack Clevis

Material: Aluminum

Surface: Anodized

Dimension: In Inch or Millimeters

Shock Swivel Clevis

Material: Chromoly Steel

Surface: White Zinc Plating

Dimension: In Inch or Millimeters

Clevis Joint

Material: Carbon Steel

Surface: Customized

Dimension: Customized

Request Full Catalog

Why Clevis Rod Ends Are Important?

Clevis rod ends—also known as clevis joints or clevis end fittings—are mechanical connectors featuring a clevis yoke and pin, designed to link components securely while allowing controlled motion and flexibility.

Clevis rod ends play a key role in connecting moving parts. Their simple yet strong design allows secure load transfer while keeping assemblies flexible. From agricultural machinery and construction equipment to automotive and industrial systems, clevis rod ends are trusted for their durability, quick installation, and wide adaptability.

| Application | Standard Model | Features | Standard Materials |

|---|---|---|---|

| ASAE S278.6 ISO 730 | Quick-release High Corrosion Resistant Includes Locking Pin. | Carbon Steel (Hot-Dip/Zinc Plated) |

| Din71752 ISO 8140 | High Thread Precision Tight Tolerances | Medium Carbon Steel(C45) Phosphate/Zinc |

| ASME B30.10 EN 1677 | Forged With Safety Latch Clear WLL Marking | Alloy Steel (G80/G100) |

| SAE J847 ISO 1102 | Heavy-duty Design High Strength Fatigue Resistant | Hot Forged Alloy Steel |

| DIN71752 | High Dimensional Accuracy Easy Assembly | Stainless Steel (304/316) |

About SYZ ROD ENDS

With over 26 years of precision manufacturing expertise, we specialize in delivering durable, high-performance custom metal components for demanding industrial and automotive applications. Our 35,000 sq ft ISO 9001-certified facility is equipped with advanced CNC machining centers, heat-treatment lines, and automated inspection systems, ensuring every part meets strict performance, reliability, and safety standards.

Engineering & Design Support

Your Partner in Innovation

Accelerate your product development with our complete engineering resources. From concept to validation, we provide the technical data and files you need to integrate seamlessly and design with confidence.

Comprehensive PDF Datasheets / 3D STEP Files for instant CAD integration / 2D CAD Drawings (DWG, DXF) for precision detailing

OEM / ODM Customization

From Concept to Global Delivery

Requirement Analysis-Define application, performance metrics, and target cost

Engineering Design & 3D Modeling- Transform ideas into CAD drawings and 3D models

Prototyping & Validation-Rapid prototyping and testing for design accuracy

Tooling & Mass Production-From approved samples to large-scale manufacturing

Quality Assurance-Rigorous inspections for consistent performance

Packaging & Services

Beyond Products, We Deliver Value

We ensure your products arrive safe, secure, and ready for market. From professional standard packaging to fully customized solutions, our services are designed to support your brand on a global scale.

White-label box packaging for a clean, brand-ready look / Multi-language manuals for global users / Tailored solutions with reliable worldwide logistics support

GET A LATEST PRICE

Send us an email: [email protected]

Custom Clevis Details

Precision Threads

High-precision thread rolling/cutting ensures smooth, burr-free threads.100% inspect- ed with go/no-go gauges for perfect assembly.

Flawless Surface Finish

We offer eco-friendly zinc plating (per ASTM B633), zinc-nickel alloy, and hot-dip gal- vanizing, passing 48-96 hour salt spray tests to prevent rust.

Clear Laser Marking

We laser-etch batch numbers, WLL, specifications, or your logo upon request for com- plete traceability.

Strict Tolerance Control

Critical dimensions like pin hole and jaw opening are strictly controlled to drawing specifications, ensuring lot-to-lot consistency.

Custom Options

Material

Carbon Steel

1018 / 1020 / 1045 / A3 / Q235 etc.

Chromoly Steel

4130 / 4040 / 4340 / 8620 / 8640

Stainless Steel

303 / 304 / 316 / 412 / 17-4 etc.

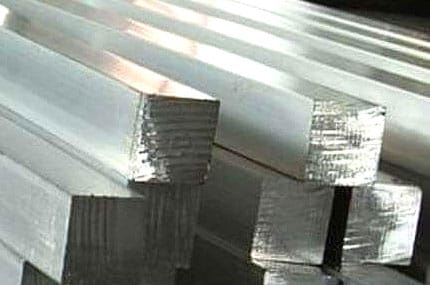

Aluminum Alloy

5052 / 6061 / 6063 / 6082 / 2017 / 7075 etc.

Titanium

TA2 / TC3 / TC4 / Ti-6al-4v / TAV6E / TC10 etc.

Surface Treatment

White/Yellow Zinc Plating

Hard Chrome Plating Polishing

Blackening Treatment

Powder Coating

Original Raw Material

Thread and Sizes

Female LH/RH Thread

Male LH/RH Thread

Metric Sizes

Inch Sizes

Applications

Automotive

Pneumatics

Machinery

Electricity

Aerospace

Why Choose Us?

Over 20 Years of Manufacturing and Export Experience

With more than two decades of experience in the manufacturing and export industry, we have built a reputation for delivering high-quality products and dependable service worldwide. Our expertise allows us to consistently meet the diverse needs of our clients, ensuring satisfaction with every order.

Collaboration with Over 30 External Suppliers

We work with a network of over 30 trusted suppliers, enabling us to offer a wide variety of materials and solutions. This collaborative approach enhances our ability to provide customized products, ensure timely deliveries, and adapt to specific customer requirements.

Quality Certifications (ISO, RoHS, SGS, CE)

We are committed to maintaining the highest standards of quality. Our products are certified by internationally recognized quality assurance programs such as ISO, RoHS, SGS, and CE, guaranteeing that every item meets stringent quality and safety regulations.

Guaranteed Delivery Time

We understand the importance of on-time delivery, which is why we offer a reliable delivery time guarantee. By optimizing our manufacturing processes and collaborating closely with logistics partners, we ensure that your orders arrive as scheduled, without any delays.

Frequently Asked Questions

What Are the Common Applications of Clevis Rod Ends?

Clevis rod ends are commonly used in agricultural machinery, automotive suspension systems, construction equipment, and industrial automation. They provide a secure connection in applications requiring precise movement and load transfer.

What's the MOQ and Lead Time for Clevis Rod Ends?

MOQ: The minimum order quantity (MOQ) for clevis rod ends is typically 50 pieces or a $500 minimum order value.

Lead Time: The usual lead time for clevis rod ends is around 30–45 days, depending on the order size and customization requirements. Regular parts are usually kept in stock, ensuring faster delivery for standard orders.

Can I Get a Sample of Clevis Rod Ends Before Ordering?

Yes, samples of clevis rod ends are available at no charge. However, air freight is not included. You may either use your own freight account or consult our sales representative for the shipping cost. Sample delivery typically takes 3–5 business days.

What Are Your Payment Terms for Clevis Rod Ends Orders?

We accept payments through wire transfer or PayPal. Our standard payment terms for clevis rod ends are 30% upfront and 70% upon delivery. Special payment arrangements can be discussed based on your specific needs.

Do You Offer Custom Clevis Rod Ends with Specific Thread Types or Sizes?

Yes, we provide custom clevis rod ends tailored to your specific needs. Whether you require unique thread types, sizes, or material specifications, our team can create the perfect solution for your application.

Are Your Clevis Rod Ends ISO or CE Certified?

Yes, all of our clevis rod ends are manufactured in compliance with international standards and are ISO, RoHS, and CE certified to ensure top-notch quality and safety for various industries.

How Do I Choose the Right Size Clevis Rod End for My Application?

To choose the right size clevis rod end, consider the thread size, load capacity, and application requirements. We provide a range of sizes and can also help with custom sizing to match your specific needs. If you are not sure about the size selection, contact us for help.

Send Your Clevis Joint Inquiry

Leave your request details, we will reply you in 24hrs. Please submit the form or email to [email protected]