Heavy Duty Ball Joints for ATV UTV

Upgrade your ride with heavy duty ball joints — engineered for ATV and UTV suspension strength, built to handle the toughest off-road conditions.

Stronger Materials

Upgraded 4130 / 4340 / 300M studs and hardened housings increase strength.

Longer Life, Extreme Durability

Precision-engineered sockets—POM, composite, or steel-on-steel—deliver extended wear resistance under heavy loads.

Sealed or Greasable Options

Choose maintenance-free double-lip seals or easy-service zerk fittings.

Fits All Major ATV UTV

Polaris, Can-Am, Honda, Yamaha, CF-Moto, Arctic Cat, Kawasaki, John Deere.

About Us

Premium Heavy Duty Ball Joints Manufacturer——SYZRODENDS specialize in manufacturing high-performance ball joints for ATV & UTV applications, designed for extreme durability and precision fit. As a trusted supplier for OEMs and aftermarket brands, we offer bulk production, custom branding, and factory-direct pricing. Our ball joints are engineered for heavy-duty off-road use, ensuring superior strength and longevity. Partner with us for reliable, high-quality ATV/UTV suspension solutions!

Why Heavy Duty Ball Joints Matters?

Heavy duty ball joints are reinforced suspension joints for ATV and UTV. With upgraded studs (4130 / 4340 / 300M alloy steel), hardened housings, and precision sockets—POM, semi‑POM composite, injection‑molded, or steel‑on‑steel—they outlast stock joints in harsh off‑road use.

ATV and UTV vehicles face constant impacts, mud, and heavy loads. Standard ball joints can wear quickly, leading to steering play and safety issues. Heavy duty ball joints provide extended lifespan, stable handling, and confidence for demanding off-road performance.

What Is an ATV?

An ATV, or All-Terrain Vehicle, is a small, lightweight four-wheeler designed for single riders. Popular in farming, trails, and recreation, ATV ball joints keep suspension stable under rough terrain and frequent steering movements.

What Is a UTV?

A UTV, or Utility Task Vehicle, is larger and built for multiple passengers and heavy loads. Common in work and off-road racing, UTV ball joints handle stronger impacts, providing durability and control for demanding suspension systems.

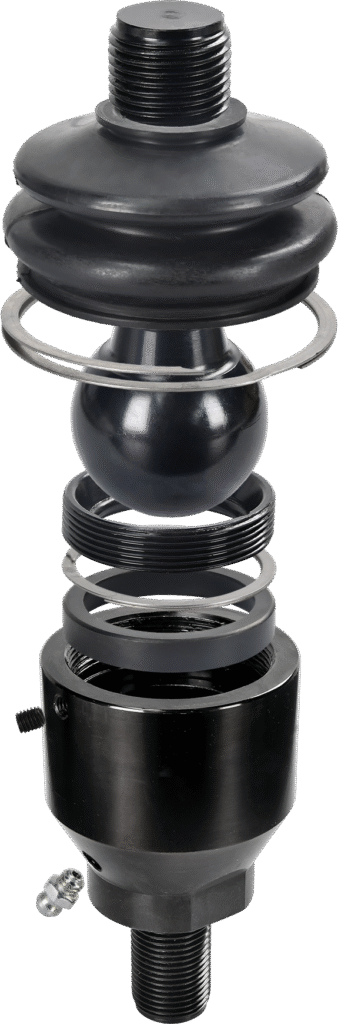

Construction & Materials

Castellated nut replicate OE

To replicate the OE look, and provide the security of split pin installation for nut retention.

Shank

Lengthened threaded shank for dual fasterning

High quality Chloropene rubber boot

The CR material is treated for high ozone and weather resistance, with low flammability and strong tolerance to oil, fuel, and chemicals. It provides better protection against contaminants and ensures longer service life.

Heavy duty boot retaining clip

Ensure boot remains seated even at maximum ball joint articulation (increased over standard where possible).

Ball stud

Material: high strength 4130 chromoly alloy steel is used to offer greater strength. The finished ball stud offers lower friction and high performance resulting in smoother operation and a longer lasting component. Smooth grease groove channel ensures the grease is distributed.

Hardness: heat treatment is applied to the ball studs making the hardness of the ball surface 20-25 Rockwell with depth of .3 - .5mm. This hardening process aids the ball stud in reducing wear, providing for longer life of the component.

CNC machined housing

Precise CNC machining ensures a perfect components used to make up the ball joint mechanism resulting in smoother operating and longer lasting componentry.

Finish

Ball

25mm Ball for higher shear and ball strength.

Bushing Cup

POM-M90 bearing material for long life

ATV & UTV Models We Support

Frequently Asked Questions

What are heavy duty ball joints?

Heavy duty ball joints are high-strength suspension components designed for off-road vehicles like ATVs and UTVs. Unlike stock joints, they feature upgraded materials (such as 4130, 4340, or 300M steel) and reinforced sockets, making them more durable and resistant to wear under extreme conditions.

Why should I upgrade to heavy duty ball joints?

Upgrading to heavy duty ball joints provides better performance and durability, especially for off-road enthusiasts. They are designed to handle more extreme impacts, reduce steering play, and increase the lifespan of your suspension components. Perfect for ATV and UTV riders tackling tough terrains.

Are heavy duty ball joints compatible with all ATVs and UTVs?

Yes, our heavy duty ball joints are designed to fit a wide range of ATV and UTV models, including popular brands like Polaris, Can-Am, Honda, Yamaha, and Kawasaki. Please check our compatibility guide to find the right fit for your vehicle.

What materials are used in heavy duty ball joints?

Heavy duty ball joints typically use high-strength materials like 4130 and 4340 alloy steel for the studs, and hardened or reinforced sockets made from POM, semi-POM composites, or steel-on-steel. These materials ensure higher durability and resistance to wear under tough off-road conditions.

How often should I maintain or replace heavy duty ball joints?

While heavy duty ball joints are designed for long-term use, regular inspections are essential. Check for signs of wear, such as excessive play or noise, especially after heavy use. Regular maintenance, including keeping the joints lubricated (if greasable), will ensure optimal performance.

Are Your heavy duty ball joints ISO or CE Certified?

Yes, all of our heavy duty ball joints are manufactured in compliance with international standards and are ISO, RoHS, and CE certified to ensure top-notch quality and safety for various industries.

How do I choose the right heavy duty ball joints for my ATV or UTV?

To choose the right heavy duty ball joints, you need to know your ATV or UTV model, year, and make. It’s important to ensure compatibility with your vehicle’s suspension design. If you are not sure about the size selection, contact us for help.

Why Choose Us?

Over 20 Years of Manufacturing and Export Experience

With more than two decades of experience in the manufacturing and export industry, we have built a reputation for delivering high-quality products and dependable service worldwide. Our expertise allows us to consistently meet the diverse needs of our clients, ensuring satisfaction with every order.

Collaboration with Over 30 External Suppliers

We work with a network of over 30 trusted suppliers, enabling us to offer a wide variety of materials and solutions. This collaborative approach enhances our ability to provide customized products, ensure timely deliveries, and adapt to specific customer requirements.

Quality Certifications (ISO, RoHS, SGS, CE)

We are committed to maintaining the highest standards of quality. Our products are certified by internationally recognized quality assurance programs such as ISO, RoHS, SGS, and CE, guaranteeing that every item meets stringent quality and safety regulations.

Guaranteed Delivery Time

We understand the importance of on-time delivery, which is why we offer a reliable delivery time guarantee. By optimizing our manufacturing processes and collaborating closely with logistics partners, we ensure that your orders arrive as scheduled, without any delays.

Manufacturing Excellence

Advanced Production & Quality Control for Superior ATV/UTV Parts