If you’re managing a $300,000 self-propelled sprayer, the last thing you want is downtime during peak season because of a $50 bearing failure. Just last month, I got an urgent call from a customer—his Case IH sprayer’s boom arm seized up right in the middle of the spring planting window. After inspection, we found that the rod end on the hydraulic cylinder connection had corroded and failed, costing him two full days of spray operations. Not cheap when you’re racing against the weather.

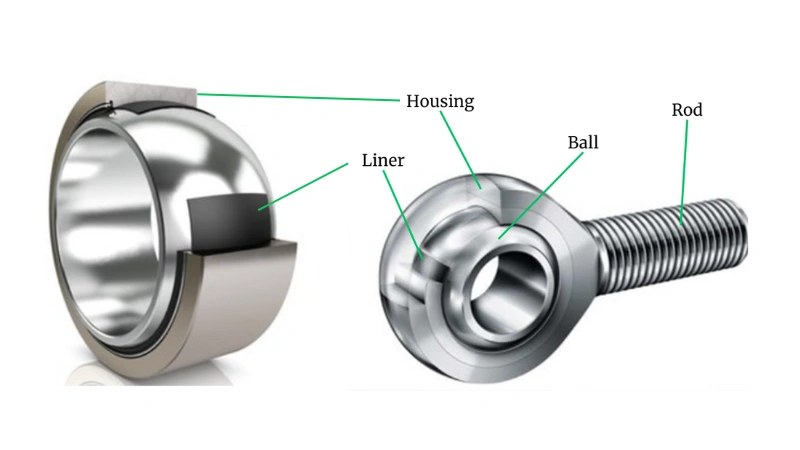

This seemingly insignificant component, formally called a rod end (or spherical bearing), acts as the “joints” of agricultural sprayers. From 30-meter boom folding systems to precision suspension mechanisms and the latest AI-powered robotic spray arms, these things are everywhere—and when they fail, everything stops.

Why Agricultural Sprayers Need Rod Ends

Here’s what makes rod ends special: their spherical design. The inner race is a precision-ground ball, and the outer race is a matching spherical housing that allows multidirectional rotation, compensating for angular misalignment of ±6° to ±15°. This is critical for agricultural equipment operating on rough terrain—and believe me, fields aren’t exactly smooth parking lots.

I’ve seen farmers try to save money by using regular bushings instead of rod ends. Within a quarter, severe wear caused a 3° angular deviation in the boom arm. Don’t underestimate that 3°—spray height deviation directly leads to a 15% drop in coverage, and the cost of wasted chemicals and re-application far exceeds the price difference of proper rod ends. Penny wise, pound foolish.

Four Main Types

1. Steel-on-Steel Lubricated ($15-40/unit)

Highest load capacity, suitable for boom main folding hydraulic cylinders, but here’s the catch—you need to grease them every 50 operating hours. A typical sprayer has 20-30 grease points, which means 10 lubrication sessions per busy season at approximately $1000 in labor costs. That adds up fast.

2. PTFE Self-Lubricating ($35-50/unit)

These feature a PTFE liner between the steel ball and housing for maintenance-free operation. According to GGB’s technical documentation, their GAR-MAX® filament wound composite bearings achieve 1500-2000 operating hours on John Deere sprayers. They’re 30-50% more expensive initially, but stick with me here—the 5-year total cost is actually lower.

3. Composite Material ($40-60/unit)

The igus igubal series uses engineered plastics, weighing only 1/4 of steel equivalents with completely lubrication-free operation. Perfect for precision agricultural robotics applications where weight matters.

4. Stainless Steel High-Temperature

Used in special scenarios like greenhouse steam sterilization systems. You won’t see these much in field sprayers.

Application 1: Boom Arm Folding Hydraulic Cylinder Connections

Modern self-propelled sprayers feature boom arms spanning 25-40 meters, folding through 3-5 hydraulic cylinder sections. Each cylinder requires rod ends at both ends to compensate for angular misalignment; otherwise, side loads will deform the cylinder body—and that’s a repair bill you don’t want.

Take the Case IH Patriot 4440 as an example: a single boom section weighs approximately 1000kg and folds using 2 hydraulic cylinders. Now here’s something most people get wrong: the hydraulic cylinders don’t vertically lift the boom arm—they’re mounted near the pivot point, creating a lever structure.

Because the force arm (distance from cylinder pivot to rotation axis) is much shorter than the resistance arm (distance from boom center of gravity to rotation axis), the leverage ratio typically ranges from 1:3 to 1:5. This is where the physics gets interesting: even though the boom weighs 1000kg (approximately 10,000N), the hydraulic cylinder actually bears a static load of 15-25kN per cylinder (calculated using g=10m/s² and leverage ratio of 1:3-1:5).

When you factor in the dynamic coefficient of 1.5-2x for folding impact, peak loads hit 22-50kN. Add side loads and the agricultural equipment safety factor of 2.5-3, and you’re looking at actual selection in the 55-150kN range. In real-world engineering practice, boom main folding cylinders typically use heavy-duty rod ends rated for 60-100kN.

5-Year Cost Comparison

Let’s do the math on what this actually costs you (based on 20 rod ends):

Traditional Steel-on-Steel Lubricated:

- Initial purchase: $25 × 20 = $500

- Service life: 2 years

- 5-year replacements: Once in year 2, once in year 4

- Total purchase cost: $500 (initial) + $500 (year 2) + $500 (year 4) = $1500

- Annual maintenance: 10 lubrications × 2 hours × $50/h = $1000/year

- 5-year total cost: $1500 + $5000 = $6500

PTFE Self-Lubricating:

- Initial purchase: $40 × 20 = $800

- Service life: 4 years

- 5-year replacements: Once in year 4

- Total purchase cost: $800 (initial) + $800 (year 4) = $1600

- Annual maintenance: $0 (maintenance-free)

- 5-year total cost: $1600 + $0 = $1600

The self-lubricating solution costs 60% more upfront—I get it, that sticker shock is real. But here’s what the numbers actually show: approximately 75% savings in 5-year total cost ($1600 vs $6500). And this doesn’t even account for the opportunity cost of downtime during peak season when you’re supposed to be spraying, not greasing bearings.

Application 2: Angular Compensation in Boom Suspension Systems

Boom arms require suspension systems to maintain constant ground clearance (typically 18-24 inches). Spray height deviation of ±2 inches causes 15-20% variation in coverage—and when you’re dealing with expensive chemicals, that’s money literally being sprayed on the ground. Each joint in the suspension linkage requires rod ends for free articulation.

Traditional bushings only allow single-axis rotation, causing binding when the boom oscillates. Spherical bearings allow ±10-15° multidirectional angular compensation, completely eliminating binding. GGB’s technical whitepaper shows that suspension systems using GAR-MAX® filament wound composite bearings improve boom stability by 30% compared to bushings—and I’ve seen this improvement firsthand in the field.

Material Selection for Chemical Corrosion Environments

Here’s where things get nasty: rod ends in boom suspension systems are directly exposed to spray environments. I’ve run tests on this myself—ordinary zinc-plated carbon steel rod ends in glyphosate solution show extensive coating failure and severe internal corrosion after just 6 months.

The numbers tell the story:

- Stainless Steel + PTFE: $60, 3-5 year life, annualized cost $12-20

- Zinc-Plated Carbon Steel: $25, 6-12 month life, annualized cost $25-50

One farm I work with switched to GGB GAR-MAX® series three years ago and hasn’t replaced them yet. Boom stability improved noticeably, and they’re saving approximately 8% on chemicals. That’s real money back in their pocket.

Application 3: Precision Agricultural Robotic Dual-Arm Spray Systems

Traditional sprayers use “blanket” application, wasting 90% of chemicals on non-target areas. The new direction in precision agriculture is AI vision recognition combined with robotic arm targeted spraying, reducing chemical usage by 80-95%. The environmental impact alone is significant, not to mention the cost savings.

According to igus’s agricultural robotics application cases, some advanced precision spray robots are equipped with multi-degree-of-freedom robotic arms for targeted application after AI vision identification. Each joint of these robots uses igus igubal composite material rod ends for flexible movement.

Why Choose igus for Robotic Arms?

Here’s what makes them the go-to choice:

- Ultra-lightweight: 50g vs. 200g steel, 75% weight reduction—critical when you’re moving these arms hundreds of times per hour

- Zero lubrication: Grease contaminates farmland; composite materials are naturally self-lubricating. No grease means no soil contamination

- Maintenance-free: Think about this—for 10 robots with 160 bearings, traditional solutions require 160 lubrication points weekly. That’s completely impractical for a commercial operation

Comparison Table:

| Parameter | Traditional Steel | Igus Composite |

|---|---|---|

| Weight | 200g | 50g |

| Load Capacity | 50kN | +5-15kN |

| Maintenance | Every 50h | Zero maintenance |

| 5-Year Cost (16 units) | $4,400 | $720 |

Selection Guide and Procurement Recommendations

Decision Flow

Step 1: Assess Load Requirements

- >50kN → Steel-on-steel lubricated (heavy-duty applications like boom main folding cylinders)

- 20-50kN → Stainless steel PTFE type

- <20kN → Any type works, but I’d prioritize maintenance-free

Step 2: Assess Environment

- Exposed to spray → You need corrosion-resistant materials, period

- Protected → Carbon steel is acceptable, but honestly, stainless is worth the premium

Step 3: Assess Maintenance Capability

- Limited maintenance capability → Go maintenance-free, save yourself the headache

- Large-scale equipment (10+ units) → Strongly recommend maintenance-free—trust me on this

Typical Scenario Solutions

Self-Propelled Sprayers (Case IH, John Deere):

- Boom main folding cylinders (4-6 units): Stainless steel PTFE, $60-80

- Suspension system (10-15 units): GGB GAR-MAX® composite, $45-60

- Total investment: $1500-2500

- Expected ROI: Save $4000-6000 in maintenance costs over 5 years

Small to Medium Tow-Behind:

- Suspension system: Stainless steel PTFE, $45

- Folding cylinders: Carbon steel lubricated, $25 (acceptable if budget-limited, though not ideal)

- Total investment: $600-1000

Precision Agricultural Robots:

- Robotic arm joints (16-24 units): igus igubal, $40-60

- Per-unit investment: $800-1500

- Large-scale deployments receive 15-25% bulk discounts—definitely worth asking about

Procurement Checklist

Before you place that order:

- Load calculation (static + dynamic + safety factor 2.5-3)

- Bore diameter matches hydraulic cylinder pin

- Material certification (stainless steel grade, PTFE specifications)

- Stock up 2-3 months before peak season—waiting until you need them is asking for trouble

- Maintain 10-20% spare inventory

Core Recommendations

Remember these three things:

- Calculate 5-year total cost, not just initial price — Maintenance-free solutions cost 60% more upfront but save 75% over 5 years. Do the math for your operation.

- Prioritize maintenance-free for critical positions — Even on tight budgets, at least use maintenance-free types in suspension systems and hard-to-access locations. Your future self will thank you.

- Stock up early — Two months before planting season is peak procurement time. I’ve seen operations lose days waiting for parts because they ordered too late.

About SYZ Machine

Beyond the established brands mentioned in this article, if you’re looking for high-value custom solutions, consider SYZ rod ends for agricultural machinery. We’re a professional rod end manufacturer providing OEM/ODM manufacturing services to multiple leading North American brands, offering:

- Custom Capabilities: Precision CNC machining with material and specification customization based on your specific application requirements

- Quality Assurance: Strict ISO compliance, full material traceability, and certification documentation provided

- Flexible Delivery: Support for small-batch rapid delivery (50-500 units) as well as large-scale production runs

- Technical Support: Free load calculation assistance and selection guidance from our engineering team