A while back, I came across a discussion on an agricultural machinery forum where a farm owner was venting about his John Deere 336 baler—said he was constantly stopping mid-harvest to adjust tucker fingers, and it was killing his productivity. An experienced user chimed in and nailed the problem: those original eyehook connections. After switching to ball joint rod ends, the guy barely had to touch them all season. That discussion stuck with me because it perfectly illustrates something I’ve noticed over the years: rod ends (spherical rod end bearings) might be among the smallest, least flashy components on a baler, but when they fail or wear out, the whole machine suffers.

What Are Rod Ends and Why Balers Need Them

Watch a baler running for a few minutes and you’ll spot something interesting: the machine has joint positions all over the place that need to connect parts while letting them move. Try using fixed connections—welding or rigid bolts—in those spots, and you’re asking for trouble. They’ll bind up or snap from the angular stress. That’s the whole point of rod ends.

Think of a rod end as a ready-to-install mechanical joint with three key pieces: a spherical bearing (that’s a precision-ground steel ball allowing multi-directional movement, kind of like your shoulder joint), a housing (the metal shell holding everything together and taking the loads), and a threaded connection (for bolting to other parts and adjusting the length when you need to dial things in).

Here’s why balers lean on rod ends so heavily:

- Angular misalignment – As baler components move, angles change constantly. Tucker fingers sweeping hay into the chamber? The connecting rod angles at both ends are shifting the whole time. Spherical bearings handle that without breaking a sweat.

- Vibration absorption – Square balers with plungers? The vibration is brutal. Rod ends soak it up without hammering the rest of the machine with stress.

- Adjustment capability – Lots of spots need fine-tuning—tucker finger timing being the classic example. Threaded rod ends let you dial in the length right there in the field.

- Harsh environment tolerance – Balers work in dirt, moisture, and temperature swings that would kill lesser components. Quality rod ends with sealed designs and corrosion-resistant materials just keep working, outlasting plain bushings by a mile.

Rod ends come in two main types: Maintenance-free (PTFE-lined with a self-lubricating layer—no greasing needed) and maintenance-required (metal-to-metal contact, needs regular grease, but handles heavier loads). Precision grade rod ends hit ±0.01mm ball tolerances, which is tight enough to keep everything running smooth. Now let’s look at where these things actually work in a baler.

The Two Most Critical Applications: Tucker Fingers and Hydraulic Linkages

Tucker Finger Assembly

If there’s one place where rod ends prove their worth, it’s the tucker finger assembly. Tucker fingers have a deceptively simple job: precisely feed hay from the pickup into the bale chamber. Plunger pulls back, fingers sweep across and push hay in. Plunger moves forward, fingers retract. Mess up that timing even slightly, and you’ll get inconsistent bale density or screw up the knotter tie timing.

Tucker rods with rod ends link the tucker shaft to the drive mechanism. Why can’t you use something simpler? Because the tucker shaft is rotating while the drive mechanism is doing complex back-and-forth motion, so that connection angle is always changing. Ball joints in rod ends let everything move smoothly while still maintaining positive drive.

The Evolution from Eyehook to Ball Joint tells you everything you need to know about why better rod ends matter:

Original eyehook design – Simple, cheap, but problematic. From a mechanical standpoint, an eyehook creates line contact. As it wears, that degrades to point contact, and clearance grows fast. I’ve seen this play out dozens of times: brand new baler, tucker timing is spot-on. Give it a season or two, and that eyehook-to-pin clearance opens up, you get wobble, timing goes off, and suddenly you’re making constant adjustments. Worse yet, the connection works loose over time no matter how many times you tighten it.

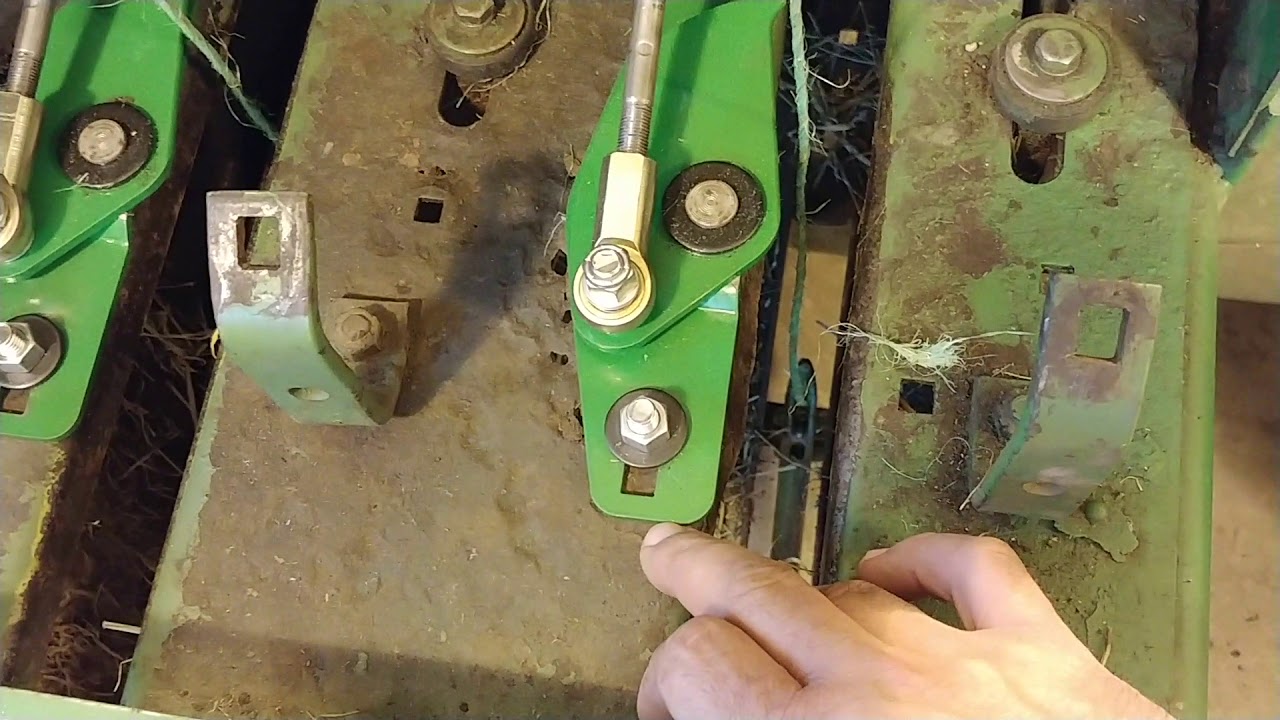

Modern ball joint design – Threaded steel rod with brass ball joints at both ends. That ball is ground to ±0.01mm tolerance, giving you surface contact instead of line contact. Stress spreads evenly, fit is incredibly tight—”creates a tighter assembly with a lot less play,” as the parts catalogs say. The spherical design accommodates 10-15° of angular misalignment, which is exactly what you need for that non-coplanar motion between the tucker shaft and drive mechanism. Add lock nuts, and once you’ve got it dialed in, it stays put. I’ve watched upgraded balers run three, four seasons without needing tucker timing adjustments.

Retrofit kits are out there for a ton of John Deere models: 24T, 224T, 336, 346, 327, 337, 347, 328, 338, 348—the list goes on.

Source: Youtube creator Gate City

Hydraulic Cylinder Linkages

Hydraulic systems in balers drive all kinds of functions—bale discharge gates, chamber doors, latch mechanisms. Here’s the challenge: hydraulic cylinders give you linear motion (in and out), but gates and doors need rotational motion (swinging on hinges).

Take a round baler discharge gate. It’s hinged on one side and needs to swing open maybe 90-120°. If you tried connecting the cylinder rod straight to the gate with a rigid link, it wouldn’t work. As that gate opens, the angle between it and the cylinder changes from around 30° to 120°. A rigid connection would create massive side loads—either binding everything up or ripping the mounts apart.

The fix? An actuator arm with rod ends at both connection points—one end on the cylinder rod, the other on the gate. When the cylinder extends, the arm pivots and converts that linear push into the gate’s rotational swing. Rod ends at both ends let the arm pivot relative to both the cylinder and the gate, handling those continuous angle changes through the whole motion.

Here’s what most people miss: rod end spherical bearings absorb side loads. As the gate follows its arc, lateral forces get soaked up by the rod end instead of hammering the hydraulic cylinder rod. That protection keeps the cylinder’s piston seals from getting torn up by side loading, which can easily double your cylinder service life.

Bale latch mechanisms rely on the same principle for precision control. There’s a patent (US4407190A) that describes the setup: “actuator arm connected between latch hook and hydraulic cylinder” with rod ends at the pivot points enabling proper engagement and disengagement. The latch needs to approach at a specific angle to catch reliably. The rod end’s spherical bearing allows just enough angular adjustment that even with minor geometric variations—and trust me, there are always variations in agricultural machinery—that latch still catches every time.

These spots are safety-critical. Gate or latch failure can be dangerous, so precision grade rod ends are the only smart choice for long-term reliability.

Chamber Systems and Other Key Locations

Compression Rods and Tension Systems

During bale formation, the chamber takes a beating: material compression creates uneven pressures, components vibrate like crazy, and material wants to shift around and cause plugs.

Round baler compression rods – You’ve got several rods running across the bale chamber, mounted through adjustable rod ends to the chamber structure. Their job? Compress hay against the belts or tines for even compression, stabilize components to cut down vibration and chatter, and keep material from shifting into positions that’ll cause plugging.

Rod ends play a subtle but critical role here. The chamber configuration is dynamic as the bale forms—chamber expands as the bale grows, material compression shifts components around. Rod end pivoting capability lets those rods accommodate all that movement while still doing their job. Use fixed mounting and you’d get bending stress from all those dynamic changes, leading straight to fatigue failure.

Belt-type round balers (John Deere 566/568, for example) also use rod ends in belt tension adjustment mechanisms. Threaded rod ends give you precise tension settings while accommodating belt movement during baling. Proper tension equals consistent bale density—get that wrong and your bale quality suffers.

Knotter Trip Linkages and Other Applications

Knotter trip mechanism – Rod ends show up in the external linkages connecting the measuring wheel to the trip arm. The measuring wheel tracks bale length, and when it hits the preset length, the linkage triggers the knotter. Rod ends keep that linkage functioning reliably despite all the vibration, so timing stays consistent.

Main cylinder/plunger connection (square balers) – This is one of the highest-load applications you’ll find, requiring larger diameter heavy-duty rod ends (8-10″ on some models). Even with those heavy loads, precision still matters—the spherical bearing keeps loads properly aligned, protecting the cylinder from damaging side loads.

Steering linkages (trailed balers) and pickup height adjustment mechanisms – These are pretty standard agricultural machinery applications where rod ends accommodate angular movement and absorb shocks.

Failure Impact Ranking

| Impact Level | Component | Reason for Ranking |

|---|---|---|

| ⭐⭐⭐ | Tucker Fingers | High-frequency movement; failure directly compromises bale quality. |

| ⭐⭐⭐ | Hydraulic Gate/Latch | Safety-critical; failure causes total machine downtime. |

| ⭐⭐ | Chamber Systems | Primary driver of bale density and consistent quality. |

| ⭐⭐ | Knotter Linkages | Directly impacts tie quality and structural integrity of the bale. |

| ⭐ | Steering/Adjustments | Causes operational headaches, but usually not mission-critical. |

From Simple Pivots to Precision Bearings

Rod end technology in agricultural machinery mirrors the evolution of the industry as a whole.

Early designs had real limitations – Plain pin-and-eyelet connections offered tiny contact areas and wore out fast. Grease-fitting bushings were better, but in dusty agricultural environments, dirt contamination accelerated wear. All of them shared the same problems: maintenance-intensive, wore out too quickly, and adjustments were a pain.

Spherical bearing breakthrough – Precision ball grinding (±0.01mm tolerance) delivers minimal clearance and cuts play way down. 360° articulation capability provides true multi-directional freedom. Self-aligning characteristics automatically compensate for minor misalignments. Material advances brought high-grade steel balls with hard chrome plating—typically HRC 50+ hardness to resist abrasive wear from all that dust and sand in agricultural environments—plus hardened housings for proper support.

The tucker finger evolution from eyehook to ball joint shows this breakthrough perfectly. Same application, night-and-day performance difference.

Maintenance-free innovation changed the game – Agricultural environments make maintenance tough: you’re working remote fields, harvest season keeps you too busy to stick to a grease schedule, and dirt and moisture are everywhere. Traditional types get neglected and fail early.

PTFE-lined solutions deliver real advantages: self-lubricating (no external grease needed), contamination resistant (sealed design keeps dirt out), anti-stick-slip characteristic (PTFE eliminates micro-stiction, so high-frequency components like tucker fingers move crisper and more decisively), and extended service life (50-100% longer than maintenance-required types in harsh environments because they don’t suffer from skipped greasing).

The trade-off? 30-50% higher upfront cost, and they work best with one-directional or predominantly one-directional loads. For high-impact applications—main plunger connections taking extreme shock loads, for instance—traditional metal-to-metal with regular greasing actually holds up better. But for hard-to-access spots with relatively smooth movement (tucker fingers being the prime example), maintenance-free is worth every penny.

Industry standards like DIN ISO 12240-4 and SAE-AS6039 ensure interchangeability and set minimum quality bars. The market breaks down pretty clearly: Commercial grade (general use, cost-effective), Precision grade (±0.01mm tolerance for critical applications), Mil-Spec (highest standards, specialized heavy-duty work).

Modern innovations keep coming – Enhanced sealing systems that better protect against contaminants, advanced coatings that resist fertilizers and chemicals, application-optimized designs for different baler locations.

For older equipment owners, here’s good news: plenty of vintage balers can upgrade to modern rod end designs. Tucker finger upgrade kits are widely available, and the performance benefits show up immediately—less maintenance, better bale quality, improved reliability. The investment typically pays back in 1-2 seasons just from reduced downtime.

Maintenance and Purchasing Guide

Key Maintenance Points

Pre-season inspection isn’t optional – Before each harvest season, systematically check every accessible rod end:

Test movement by hand (should pivot smoothly, no binding). Check for play (anything over 1/8″ means it’s worn beyond limits). Visual inspection for cracks, rust, or thread damage.

Lubrication (maintenance-required types) – Follow what the manufacturer recommends (typically every 100-200 hours). Use agricultural-grade grease. Don’t over-grease—it just attracts dirt.

Preventive replacement beats emergency repairs – Don’t wait for complete failure. For critical spots like tucker fingers and latch mechanisms, plan replacement when you spot wear signs. Keep spares for high-wear positions to minimize downtime.

Purchasing Considerations

Quality indicators to look for:

- Precision specs clearly stated (±0.01mm for precision grade)

- Material certifications (high-grade steel, proper heat treatment)

- Standards compliance marks (DIN ISO, SAE)

- Brand reputation (SYZ MACHINE, RBC/Heim, ASKUBAL—these guys have proven themselves in agricultural applications)

Application-specific selection:

- High-frequency movement (tucker fingers) → Precision ball joints, seriously consider maintenance-free

- Heavy loads (plunger connections) → Prioritize heavy-duty construction

- Hard-to-access locations → Maintenance-free is worth the premium

- Lower-stress positions → Standard maintenance-required works fine

OEM vs. Aftermarket:

OEM guarantees compatibility but you’ll pay a premium. Quality aftermarket offers excellent value. What you want to avoid: ultra-cheap knockoffs for critical locations. A $15 rod end failure could easily cost you $500 in downtime during harvest.

Upgrade Opportunities

Tucker finger ball joint upgrades – If you’re still running eyehook design, an upgrade is money well spent. Complete kits are available for most models, installation is straightforward, and the performance improvement hits you immediately. ROI? Usually one heavy-use season.

Maintenance-free conversions – Replacing worn maintenance-required types with maintenance-free equivalents makes sense, especially in hard-to-access spots. Initial cost is higher, but when you factor in the labor cost of regular greasing over the equipment’s lifetime, total ownership cost often comes out lower. The advantage gets even more pronounced in remote operations or high labor-cost regions.

Core Principles of Rod End Management

- Inspect regularly – Pre-season checks catch problems before they become failures

- Replace preventively – Don’t wait for complete failure on critical locations

- Invest in quality where it matters – Tucker fingers and latches aren’t where you cut corners

- Consider total cost – Maintenance-free costs more upfront but often pencils out better long-term

- Keep critical spares on hand – Backup tucker rods and main cylinder pucks minimize downtime

- Document replacement patterns – Track your replacement history to optimize future planning

Understanding where rod ends work in your baler, how they function, and why they matter helps you maintain equipment better and make smarter purchasing decisions. These small components punch way above their weight when it comes to bale quality, reliability, and efficiency. Invest in the right rod ends at the right locations, maintain them properly, and your baler will reward you with reliable performance when you need it most—during those critical harvest periods when downtime costs real money.