When choosing between Spherical Plain Bearings and Ball Bearings, understanding the distinctions in their design, functionality, and application is essential. Both types of bearings are widely used in mechanical systems, but each excels in different environments based on their unique characteristics. In this blog, we’ll break down the differences and help you decide which one is best suited for your application.

Rolling Mechanism: Sliding vs Rolling

Spherical Plain Bearings work through sliding contact between the inner and outer rings. They typically use specialized liner materials such as reinforced nylon, PTFE (Teflon), or bronze, and often rely on lubrication (oil or grease) to reduce friction. This sliding mechanism allows these bearings to accommodate angular misalignment without affecting performance.

On the other hand, Ball Bearings operate with rolling contact, where spherical balls roll between the inner and outer races, creating point contact. This design minimizes friction but doesn’t allow for the same flexibility in misalignment, which is why ball bearings are best suited for high-speed, low-friction applications.

Applications

Spherical Plain Bearings

These spherical bearings are built to handle high radial and axial loads while compensating for angular misalignment. They’re typically found in applications that involve heavy-duty machinery, automotive suspension systems, and marine equipment—where alignment and load capacity are critical. If you need to handle large, complex loads and occasional misalignment, spherical plain bearings are your go-to choice.

Ball Bearings

Ball bearings are designed for low friction and high-speed applications. They are widely used in electric motors, bicycle wheels, and office equipment where speed and smooth operation are key. They’re excellent for environments requiring minimal resistance and high rotation speeds, but they do not perform as well when alignment is an issue.

Load Handling Capabilities

Spherical Plain Bearings

These bearings can handle significant radial loads and axial loads simultaneously, making them ideal for applications that need to carry heavy, complex loads in addition to allowing for misalignment. They are perfect for environments with slow-moving or oscillating parts where large load capacities are required, such as hydraulic cylinders or heavy machinery.

Ball Bearings

Ball bearings, by design, are great for radial loads, but they can also bear light axial loads (depending on the design). Since their contact area is limited to point contact between the balls and the races, their load-bearing capacity is typically lower compared to spherical plain bearings. They’re ideal for lighter loads and high-speed applications, such as motors and precision equipment.

Key Differences

| Feature | Ball Bearing | Spherical Plain Bearing |

|---|---|---|

| Contact Mechanism | Rolling (Point Contact) | Sliding (No Rolling Elements) |

| Load Capacity | Light to medium loads | Heavy loads, complex load handling |

| Main Load Types | Primarily radial, limited axial | Radial and axial, accommodates misalignment |

| Self-Aligning Capability | Poor (Sensitive to misalignment) | Excellent (Designed for angular alignment) |

| Speed Suitability | High-speed | Low-speed or oscillating motion |

| Typical Applications | Motors, precision machinery | Automotive suspension, heavy-duty machinery |

Key Benefits of Spherical Plain Bearings

1. Cost-Effective Misalignment Compensation

Unlike ball bearings with self-aligning features, Spherical Plain Bearings can easily compensate for misalignment without adding extra cost. These bearings automatically adjust during installation, eliminating the need for costly adjustments or machining fixes.

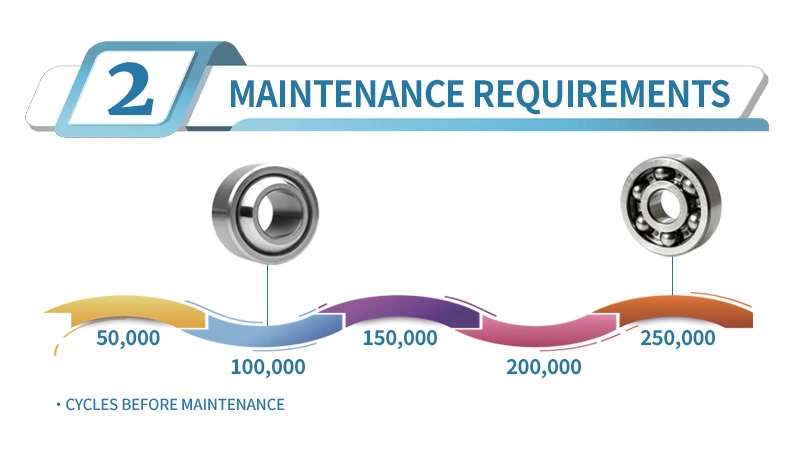

2. Minimal Maintenance Requirements

Spherical Plain Bearings are made using a sintering process that incorporates oil-impregnated metal powder. This permanent lubrication reduces the need for frequent maintenance, making these bearings much more cost-effective in the long run compared to traditional ball bearings.

3. Quiet and Smooth Operation

Thanks to their permanent lubrication, Spherical Plain Bearings operate quietly and smoothly. This makes them an excellent choice for noise-sensitive applications, ensuring a quieter environment in industrial or automotive systems.

4. Enhanced Dirt Resistance

The design of Spherical Plain Bearings helps to expel dirt and debris, especially in dusty environments. As the bearing operates, heat causes oil to seep out of the pores, pushing out contaminants and reducing the chances of dirt buildup.

5. Increased Reliability in Harsh Conditions

When a Spherical Plain Bearing fails, it typically produces a squeaking sound, but the system continues to function. On the other hand, a ball bearing failure can cause the shaft to seize, potentially damaging the motor and other components. This makes spherical plain bearings more reliable in critical applications.

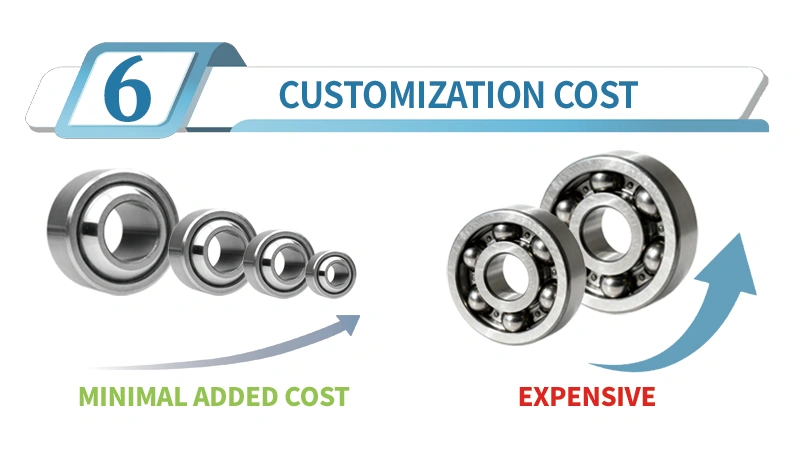

6. Customization at Low Cost

Due to their sintering manufacturing process, Spherical Plain Bearings can be custom-made with minimal added cost, especially in OEM quantities. In comparison, ball bearings require more complex processes for customization, making them more expensive to modify.

7. Compact Design for Tight Spaces

Spherical Plain Bearings have a compact design, making them suitable for applications where space is limited. Their small size allows them to be installed in areas where a ball bearing might not fit, providing more flexibility in design.

Conclusion

Choosing between Spherical Plain Bearings and Ball Bearings depends largely on the application. Spherical Plain Bearings are ideal for heavy-duty applications requiring high load capacity and tolerance for misalignment, while Ball Bearings shine in high-speed, low-friction environments where load demands are lighter. By understanding the key differences in their design, load handling, and suitability for different applications, you can make a more informed decision that ensures the optimal performance of your equipment.