Johnny Joints are heavy-duty off-road suspension joints designed to provide greater flexibility and durability than factory rubber bushings. They’re commonly found on off-road vehicles, where suspension travel and articulation are crucial. Compared to standard joints, Johnny Joints are more durable and easier to maintain and rebuild. They’re a practical option for anyone using an off-road suspension system.

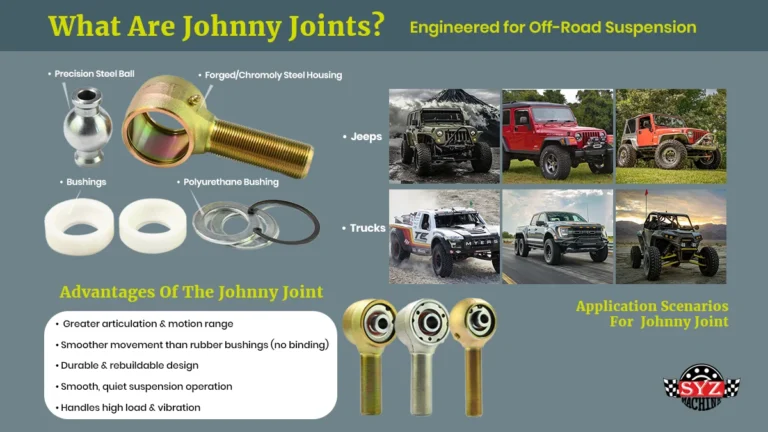

What are Johnny Joints?

The Johnny Joint is a specialized suspension joint invented by John Currie to improve the limitations of standard rubber bushings. It consists of a polyurethane bushing, a steel ball, and a chrome-molybdenum steel housing. This design, which wraps the polyurethane bushing around the steel ball, allows for a greater range of motion than rubber bushings. While standard bushings may only allow a few degrees of extension before binding, the Johnny Joint provides a greater range of rotation and arc, allowing your suspension system to cycle more freely.

Another benefit of the Johnny Joint is its ease of repair and rebuild. Instead of replacing the whole parts or hardly pressing out worn rubber bushings, you can just use simple tools and a rebuild kit. This means longer life, lower long-term costs, and consistent performance.

In short, the Johnny Joint is more than just another suspension component—it’s a durable, high-performance solution designed for Jeeps, pickup trucks, and other off-road or heavy-duty truck applications.

Why Johnny Joint is Important?

In any off-road suspension system, choosing the right joint makes the difference between a smooth ride and constant repairs. A Johnny Joint is designed to absorb shock, cut down on noise, and allow a much higher articulation angle compared to stock rubber bushings or even metal Heim joints. For builders who want a quiet operation suspension joint without giving up strength, Johnny Joints is the one.

Quick comparison:

| Feature | Rubber Bushing | Heim Joint | Johnny Joint |

|---|---|---|---|

| Durability | Wears out quickly | Very strong but harsh | Long-lasting, rebuildable |

| Noise | Quiet but limited flex | Noisy, transfers vibration | Quiet and smooth |

| Range of Motion | Limited articulation | High articulation | High articulation angle joint |

| Maintenance | Non-serviceable | Needs frequent cleaning | Rebuildable, easy upkeep |

Performance Advantages:

- Reduces harsh vibrations and shock transmission.

- Provides a smoother, quieter ride, even on rough roads.

- Provides the articulation required for professional off-road driving.

- The easy-to-maintain design extends product life.

Johnny Joint Applications

From off-road vehicles to trucks, Johnny Joints improve suspension performance. They are commonly used in 4-link setups, control arms, and trailing arms, providing smoother articulation, better durability, and enhanced ride quality.

1. 4-Link Suspension Applications

The Johnny Joint is very popular in 4-link suspension systems because it allows each suspension link to move independently while maintaining alignment and reducing stress on mounting points. Compared to traditional rubber bushings that tend to bind or wear quickly under heavy loads, the Johnny Joint offers high degrees of motion and smooth rotation, making it ideal for off-road environments and heavy-duty applications.

In high-performance 4-link suspension systems, the upper and lower links are typically connected to the frame and axle via Johnny Joints. This design provides a wider range of motion, effectively reducing suspension bind and helping the vehicle maintain stable tire contact on uneven surfaces. Consequently, off-road modifiers and engineers often choose 4-link suspensions with Johnny Joints for Jeeps and trucks to enhance their performance and reliability in off-road environments.

- Increased suspension flexibility

- Resists shock and vibration under heavy loads

- Durable, maintainable, and rebuildable for long-term use

2. Control Arm Applications

Control arms are a core element of any suspension system, connecting the upper and lower parts and directly impacting the vehicle’s steering precision and stability. Applying Johnny Joints to the control arm allows this critical connection point to maintain smooth angular changes and high load-bearing strength under complex operating conditions. For off-road vehicles, this means maintaining a stable wheel position even during high-speed impacts or on bumpy roads.

Compared to rubber bushings, Johnny Joints don’t cause excessive strain during high-angle swings, nor do they transmit the unwanted noise and vibration of Heim Joints. They strike a balance between durability and comfort, allowing the control arm to have a wider operating range while providing a quieter ride.

In Jeep and trucks upgrade solutions, Johnny Joint control arms are commonly used to improve

- Steering Response — maintaining precise wheel alignment

- Off-road Capability — increasing suspension range

- Longevity — rebuildable design for long-term reliability and easier maintenance

Control arms equipped with Johnny Joints are not only a durable replacement, but also offer improved performance and comfort.

3. Trailing Arm Applications

Unlike control arms, which mainly guide wheel position, trailing arms bear bulk of the longitudinal forces generated during braking and acceleration. Using a Johnny-Joint mounting point allows the trailing arm to rotate smoothly, preventing suspension binding and reducing wear on other components. This means better traction on loose stances and more predictable acceleration response when speeding through the desert or rock crawling.

- Maintain precise axle alignment under heavy loads and high torque.

- Provides controlled suspension extension and retraction for long-travel designs.

- Reduces the risk of stress cracks compared to rigid bushings.

- Improves ride comfort during acceleration and braking

Conclusion

The Johnny Joint is more than just a replacement part; it’s a crucial upgrade for enhancing suspension performance. It delivers exceptional flexibility, durability, and stability, ensuring precise handling and lasting reliability in complex vehicle positioning. For engineers, automakers, and tuners who demand performance and quality, choosing the Johnny Joint means choosing a professional solution built to withstand the most demanding challenges.

Wish to get more information about our Johnny Joints, check our detailed Johnny Joint introduction.

Johnny joint is a rebuildable flex Joints, it can be welded on the upper axle bracket as a fixed housing or be a threaded part of adjustment arm. Johnny joint consist of metal threaded housing, washer, bushing, ball assy and snap ring. The housing has a snap ring groove and a hole for a grease zerk.

SYZ Machine johnny joints are available in male thread and weldable sleeve. The housing is forged and then precision machined from 4130 heat treated chromoly steel. Different inner configurations are available. For instance, to use a threaded spanner nut and set screw for stronger hold and adjustable tightness; or instead of a trunnion set up, we use standard steel balls and different spacers, making it esier to use them on all different kinds of applications!

Special sizes and configurations are available in volume, send us an email with your design and we could build it for you.

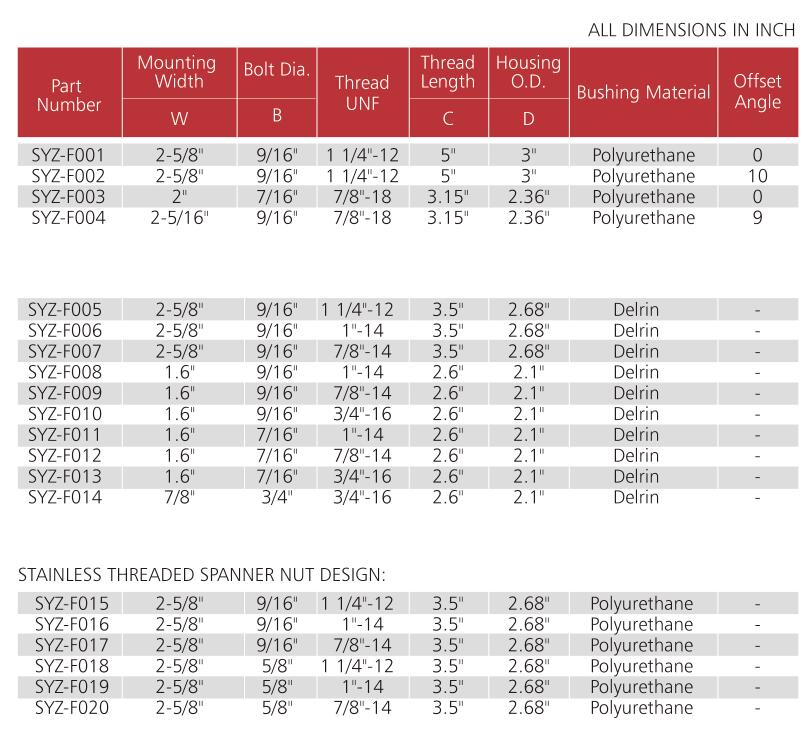

Our Regular Size: