When you’re working with rod ends—whether in racing suspension, agricultural machinery, or industrial automation—you’ll quickly run into a simple but critical challenge: making everything fit together. That’s where rod end spacers step in. These small components may not look impressive at first, but they solve alignment, clearance, and movement issues that would otherwise turn into expensive headaches.

What Are Rod End Spacers?

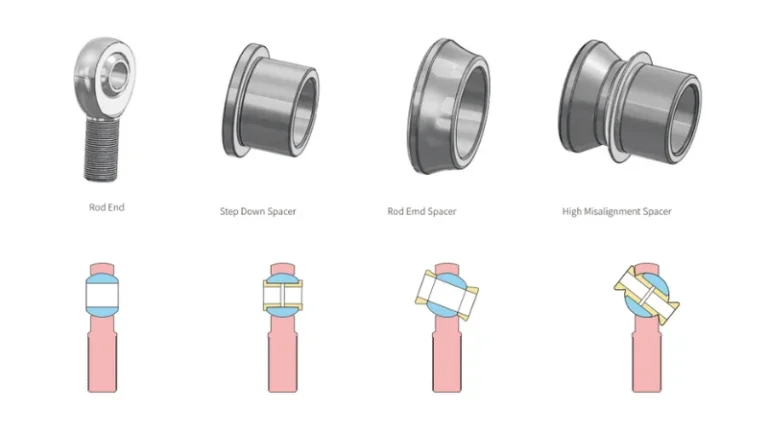

At the simplest level, rod end spacers are precision-machined sleeves or bushings that sit between a rod end and its mounting surface. Their job isn’t just to “fill a gap.” Instead, they create proper clearance, reduce bolt diameter when needed, and in some cases allow for more articulation than the rod end could achieve on its own. Without the right spacers, you risk binding, misalignment, or premature wear on your joints and brackets. For something that looks like a small metal tube, the role of spacers in suspension geometry and linkage design is much bigger than it appears.

What makes them interesting is that different designs solve different problems.

A standard rod end spacer ensures the hardware stays aligned without reducing bolt size.

A step down spacer adapts oversized hardware to smaller bolts while keeping the joint centered.

And a high misalignment spacer goes one step further—literally reshaping the articulation angle of the joint to handle the extreme movements found in 4-link suspensions or drag link systems.

So when we talk about “rod end spacers,” we’re not just talking about a single part, but a family of solutions that fine-tune how rod ends work in real-world assemblies.

Why Do We Use Them?

If you’ve ever tried bolting a rod end directly into a bracket or steering arm, you’ll know it’s not always a perfect fit. Hardware sizes don’t always match, mounting widths vary, and sometimes the joint just can’t articulate as much as your system needs. That’s exactly where rod end spacers come in. They solve those little but critical mismatches. For example, a step down spacer lets you reduce bolt size when your hardware is oversized, saving both weight and space. In setups like Panhard bars or tie rods, where there’s little-to-no misalignment, step down spacers make sure everything still locks in neatly without stressing the rod end. It’s a small part, but it prevents the kind of tolerance issues that can lead to binding or uneven wear.

Beyond just “making things fit,” spacers also optimize how rod ends perform under real-world conditions. A standard rod end spacer gives you more clearance from brackets or steering arms without reducing bolt size—a big deal when you need full strength from your hardware. Meanwhile, high misalignment spacers are the go-to choice when suspension geometry demands extreme articulation. By reducing the bolt hole size and extending the ball radius, they let rod ends swing far beyond their natural limit. That’s why you’ll find them in drag links, control arms, and 4-link systems, where lots of axial and radial movement is non-negotiable. In short, we use rod end spacers not just because they’re convenient, but because they keep systems reliable, safe, and performing exactly the way engineers and fabricators intended.

3 Rod End Spacer Types and Comparison

Step Down Spacer

A step down spacer is exactly what its name suggests: it “steps down” the hardware requirement by reducing the bolt hole size. In practice, that means you can use a smaller bolt while still keeping the joint properly centered in the bracket. The benefit here is twofold. First, it prevents oversized hardware from adding unnecessary weight or taking up more space than needed. Second, it allows fabricators to adapt rod ends to existing brackets without re-engineering the entire assembly. Step down spacers add only a little mounting width, which makes them ideal for Trac Bars, Panhard Bars, and tie rod links—applications where there’s little-to-no misalignment but plenty of load. Think of them as the “adapters” of the spacer world: they don’t dramatically change how the rod end moves, but they make sure everything fits like it should.

Standard Rod End Spacer

The standard rod end spacer is the most straightforward option, but don’t mistake simplicity for lack of importance. Unlike step down spacers, these do not reduce bolt size. Instead, they provide clearance between the rod end and its mounting surface, such as a bracket or steering arm. That clearance is critical in preventing rubbing, binding, or premature wear when the joint articulates. Imagine trying to mount a rod end flush against a bracket—every movement would scrape the housing. By introducing a standard spacer, you give the joint room to breathe, which directly translates into smoother performance and longer service life. Buyers and builders who want to preserve the full strength of their hardware (keeping the bolt size unchanged) will typically reach for these. They’re the quiet heroes in assemblies where durability matters more than fancy geometry.

High Misalignment Spacer

If step down spacers are adapters and standard spacers are protectors, then high misalignment spacers are the enablers. They are designed to push articulation angles to the max by extending the ball radius and reducing the bolt hole diameter. The result? A rod end that can swing much further than it normally could. This is invaluable in high-travel suspension setups like 3-link and 4-link systems, drag links, and control arms, where both axial and radial movement are non-negotiable. Without high misalignment spacers, the joint would bind under extreme angles, putting stress on the housing and risking failure. With them, you unlock the full range of motion while still keeping the joint secure. Yes, they slightly reduce bolt size, but the tradeoff is worth it when articulation is the top priority. For off-road builders and racing engineers, these are often the first choice when geometry gets complex.

Comparison

Each type of spacer solves a different problem, so there isn’t a “one-size-fits-all” solution.

Step down spacers are all about adapting hardware, trimming weight, and centering the joint without reworking the bracket.

Standard spacers preserve bolt size while giving much-needed clearance, making them essential in setups where strength is the priority.

High misalignment spacers trade bolt size for articulation, opening up suspension angles that rod ends can’t handle on their own.

Put side by side, the choice comes down to your project’s priorities: is it weight reduction, durability, or maximum movement? In reality, most fabricators and engineers use a mix of all three across different systems. That’s why rod end spacers aren’t just accessories—they’re precision tools that make rod ends perform the way they were intended in real-world conditions.

At the end of the day, rod end spacers are small parts that make a big difference. Whether it’s a step down spacer adapting oversized hardware, a standard spacer protecting against binding, or a high misalignment spacer unlocking extreme articulation, each plays a role in keeping assemblies safe and efficient. From racing suspensions to agricultural machinery, anywhere rod ends are used, spacers are close by making sure everything works as designed. Next time you spec out a linkage or steering setup, don’t overlook these little components—they’re often the hidden reason your system performs reliably.